Tool Design for Easy-Release (TOOSDER)

2018-2020

Summary

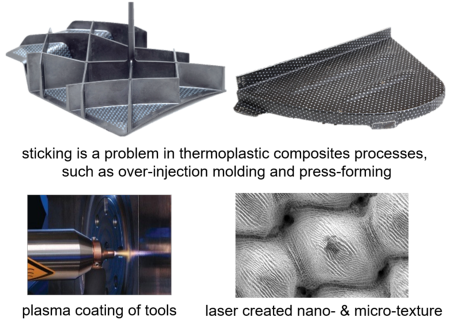

Adhesion - i.e. sticking - of a polymeric part to metallic moulds is a critical aspect in many production processes for thermoplastics and their composites, as it determines whether a the part can successfully be “ejected”. The problem of sticking is strongly influenced by the type of polymer, the tool material and surface texture, as well as the product and tool geometry. Currently, sticking of polymers to metallic tools is typically reduced by applying several low-adhesion coatings onto the tool, which are typically deposited by electro- or electroless plating. These coatings consist of chromium or PTFE containing nickel; and electroplating processes are inherently environmentally unfriendly. Reduction of chromium coatings is a theme in the area of surface engineering, but no good alternatives for these low-adhesion coatings have been found yet. Other measures to reduce adhesion for composite parts involve solvent-based release agents, which tend to reduce the surface energy of the tool surface, or film-based release media which provide an extremely smooth surface. Application of these films or solvent-based release agents is laborious and costly.

The ultimate objective of this project is to put forward tool surface designs (textures/surface treatments) with improved release properties (reduced adhesion), extended lifetime and reduced costs as well as low environmental impact. This requires fundamental understanding and quantification of the underlying mechanisms, e.g. mechanical interlocking, physical and chemical bonding, which play a role at the polymer-metal interface. The project will result in a better understanding on the adhesion mechanisms for the interface between the composite and the tool. Further, the knowledge gained will be used to develop adhesion reducing solutions based on surface engineering of the tool.

staff:

Partners:

- Industrial partners: Brightlands Materials Center & ThermoPlastic composites Research Center

- Financed via UT Connecting Industries Program