Solid-state Additive manufacturing for Enhanced microstructures through controlled Deposition (SAED)

2022-2026

The SAED project aims to exploit the advantages of the recently introduced Friction Screw Extrusion Additive Manufacturing (FSEAM) process. The solid-state nature of the FSEAM process enables the deposition of difficult to print, high-strength aluminium and magnesium alloys providing a highly refined forging microstructure with promising properties.

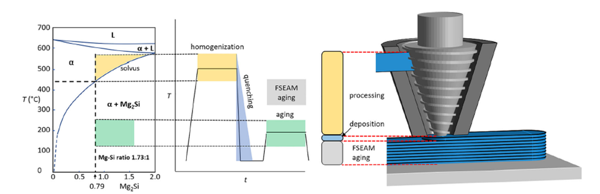

Schematic model of in-situ heat treatment cycle curing FSEAM process for AA6060. [S.S. Rezaeinejad et al. JOM 75, 4199–4211 (2023). DOI: 10.1007/s11837-023-06053-5]

The SAED project concentrates on a thorough understanding of the process-microstructure-property relationship during deposition of Al-Mg-Si alloys. The role of the thermal history on the development of the microstructure is analyzed in depth, see figure.

Developed relationships enable optimization of the process towards printing velocity, accuracy, microstructure and mechanical properties.

Funding

Financed through Sectorplan Techniek