Robust methods for in-situ consolidation during laser assisted fiber placement of thermoplastic composite tapes: towards material-based process control

2021-2025

Summary:

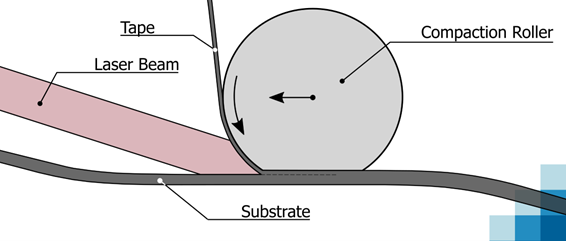

Laser assisted fiber placement (LAFP) and laser assisted tape winding (LATW) pose unique opportunities for the aerospace and automotive industry to manufacture thermoplastic composite (TPC) structures at large scale. Laser assisted fiber placement technologies provide a high degree of automation, offering a scalable solution to meet the increasing demand for lightweight and high-efficiency structures. Moreover, in-situ consolidation during laser assisted fiber placement has the potential to serve as a cost-effective single step manufacturing process for fiber reinforced thermoplastic structures. However, achieving consistent laminate quality and sufficient interlaminar shear strength for the final product remains a challenging aspect with in-situ consolidation, especially for complex parts. In-situ consolidation during LAFP is characterized by fast heating and cooling rates combined with short consolidation times. This is in contrast to autoclave or vacuum bag only (VBO) consolidation, where the heating and cooling rates are gradually controlled. Moreover, the strict requirements of the aerospace industry pose a limitation on the industrial use of in-situ consolidated thermoplastic composite parts, requiring reliability in the process.

The objective of this research is to provide novel insights in the relation between materials and process, and enabling development of material-centered process control systems. The work features material characterization of properties relevant to the AFP process, process prediction, and data analysis.

PARTNERS: