Advanced Methods for Predictive Simulation of Induction Welding for Thermoplastic Composites

2020-2024

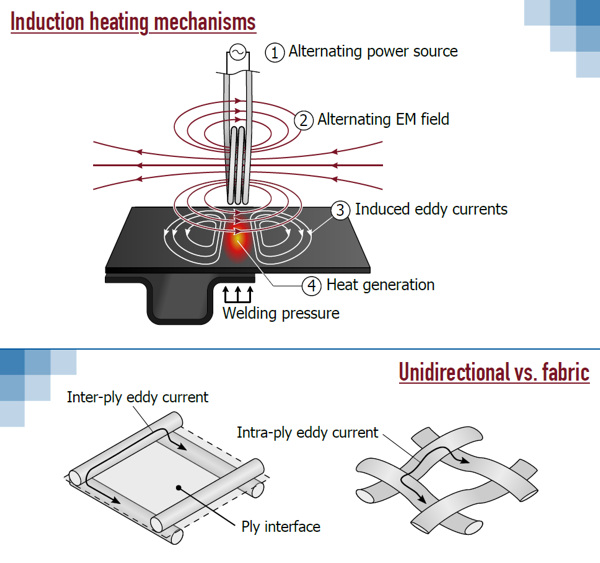

Induction welding is a key technology for the aerospace industry to assemble larger thermoplastic composite (TPC) structures from smaller components. The process currently lacks maturity as it fully relies on laborious and expensive trial-and-error procedures for the definition of processing windows. Predictive induction welding simulations are therefore required to significantly increase process understanding and reduce the process development time and costs. The main challenge here lies in obtaining accurate predictions of the temperature distribution in the assembly, requiring insight in relation between material microstructure and the highly anisotropic electromagnetic properties.

The project is split into three phases:

1. Fundamental understanding. Induction heating experiments will be performed while monitoring the thermal response, aiding insight in the governing principles.

2. Characterisation. The orthotropic electrical properties of unidirectional ply-based TPCs will be measured by developing a reliable test methodology.

3. Constitutive modelling. The insight gained and properties measured will be used as input for a simulation strategy for the induction heating response of unidirectional ply-based TPCs.