The research group “Dynamics Based Maintenance” (DBM) was founded in 2012. It originates from the “Structural Dynamics & Acoustics” (SDA) research group and became an independent research group by the appointment of prof.dr.ir. Tiedo Tinga. From 1st January 2020, prof. Tinga reduced his role in the DBM group, and dr. ir. Richard Loendersloot has taken over the lead of the group.

Evidently, the links with the other research chairs in the MS3 department remain strong, but DBM collaborates with other groups as well. In particular, there is a strong collaboration with the Maintenance Engineering, Tribology, Pervasive Systems, Civil Engineering and Industrial Engineering groups within the Maintenance Consortium TIME (Twente is Maintenance Excellence).

Since 1 February 2017 the DBM chair is supported by KIVI and has become a KIVI chair. Associated activities can be found here.

Education

MOTIVATION

Systems and structures subjected to any type of loading (static, dynamic, variable, constant) throughout their operational lifetime, experience wear, degradation and loss of functionality. To sustain their performance, maintenance activities must be performed. For critical systems generally a preventive maintenance policy is adopted, but the big challenge is then to determine the appropriate length of the maintenance interval. If this interval is too short, components are replaced before they reached the end of their service life, leading to high costs. On the other hand, replacing too late implies failure of the system with possibly large consequences. Therefore, technologies and methodologies must be developed to determine this moment accurately, thus enabling ‘just-in-time’ maintenance, and optimizing the Life Cycle Management of the system.

VISION

Our vision is that real advancements in maintenance can only be achieved when:

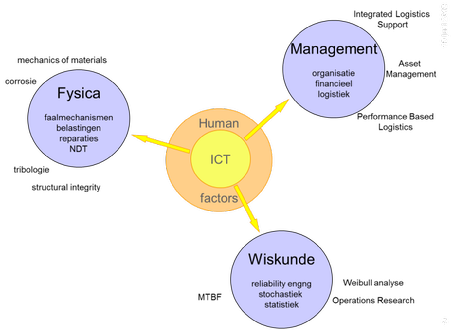

1. the multiple disciplines involved can be integrated and connected (see Figure 1):

- Physics: to determine the failure mechanisms, dynamic behaviour and loads on the system;

- Mathematics: to quantitatively analyse the failure behaviour and optimize the maintenance policies;

- Management: to optimally organize the maintenance and logistic processes, reduce costs,

- Information technology: to facilitate the collection, storage and processing of (large amounts of) data;

- Human factors: to incorporate the effects of human interaction and decisions.

2. both the system and its failure behaviour are well understood and can be quantitatively analysed by numerical models.

Figure 1 Linking the different disciplines.

RESEARCH GOAL

The goal of our research program is to develop new and innovative methods and concepts that assist to make maintenance more predictable. This is achieved by on the one hand understanding and modelling the system and its failure behaviour, and on the other hand monitoring the usage, loads, condition or (dynamic) response of the system. The aimed result is a more efficient (lower costs) and more effective (less failures and down time) maintenance process in a wide range of applications, e.g. transport, process industry, energy generation, aerospace, maritime industry, etc.

RESEARCH APPROACH

The maintenance operations can be made significantly more efficient and cost-effective, if the condition or structural health of the systems can be either monitored or predicted, thus enabling ‘just-in-time’ maintenance. To achieve that, two approaches can be followed:

- Experience-based approach: data-driven approach based on historic data. This approach requires the collection of a sufficiently large set of data, in which correlations are to be found. Often data analytics techniques are applied, that do not require any knowledge on the origin of the data. Further, accurate relations can only be obtained when the usage and operating conditions are more or less constant in time.

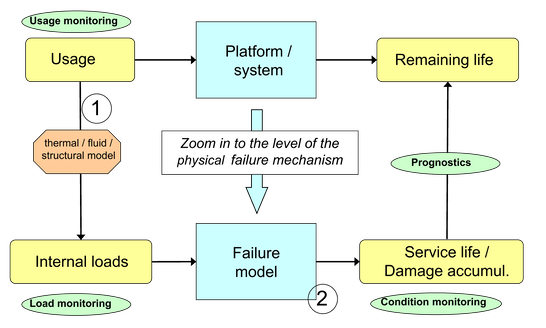

- Model-based approach: this approach is based on numerical models of the physical phenomena, like system behaviour and failure mechanisms. This is shown in Figure 2, illustrating that the relation between system usage and degradation (causing maintenance to be required) can be quantified by zooming into the level of the physical failure mechanisms. When the loads on the component level can be assessed, prediction of the time to failure is feasible and a predictive maintenance policy can be developed.

Figure 2 Relations between usage, loads and degradation of a system.

Our research program addresses both approaches, since the optimal approach is expected to be a combination of these two. However, it is our vision that knowledge on the system and failure behaviour should always guide the method development, even if the experience-based approach is followed.

In this field, an increasing interest is observed in the combination of structural health and condition monitoring systems with smart, autonomous sensors. These sensors operate using the energy harvested by local energy sources, such as the operational vibrations of the structure, and send their information (via a wireless network) to a central analysing unit, possibly after some local processing. The huge advantage is the possibility to apply these smart, autonomous sensors in hard to reach locations (i.e. rotating environment, hazardous environments, offshore wind turbines).

Applications for structural health monitoring are mostly found in the aerospace and wind turbine industry, but also in the naval and water management industry. More general condition based and predictive maintenance strategies can be applied in a wide range of industries, e.g. process, energy generation, transport, military and aerospace.

To summarize, our research focuses on the following topics, which together enable to achieve the required maintenance improvements:

- Vibration based Structural Health Monitoring methods: damage identification based on either experimental modal analysis, operational modal analysis or time domain methods;

- Damage identification based on propagating waves, such as ultrasonic methods like guide waves and nonlinear ultrasonics;

- Development and integration of smart, autonomous wireless sensor systems for monitoring loads and system response;

- Modelling of failure mechanisms and development of predictive maintenance strategies based on monitoring of system loads or usage;

- Development of intelligent data analysis methods to interpret the monitoring data;

- Development of decision support tools to assist in selecting the most appropriate methods or techniques (e.g. condition monitoring, prognostics, critical parts);

- Development of methods to optimize the maintenance process, by finding the best balance between maintenance costs and resulting system availability.

PARTNERS

Collaborations with industrial partners and other research groups within the University of Twente is embodied by the participation in the knowledge and research centre TIME (Twente is Maintenance Excellence) and the network of World Class Maintenance. Also a close cooperation with the Netherland Defence Academy (NLDA) exists, resulting in a number of collaborative research projects. Finally, we collaborate with many companies in various sectors of industry. Details on the research and the industrial partners involved can be found on the project pages. International partners are found in the European projects in which the group is active.