In the research theme Energy System Integration we explore and analyze ways to integrate renewable energy in our present energy infrastructure. We want to develop innovative strategies to combine energy carriers such as electricity, heat, gas and fuels for heating and cooling of the built environment and industry, power and water consumption and transportation. The aim is to utilize synergies in the energy system to maximize efficiency, minimize costs, reduce emissions and energy losses. Special attention is given on using hydrogen as a future energy vector and the development of fuel cells and electrolysers for energy applications or to balance the energy grid.

- Highly Efficient Super Critical Zero Emission Energy System

Project description

Wind and sun will be central energy sources of a climate neutral Europe 2050, bringing with them the need to balance weather dependent differences between supply and load. Conventional gas turbines can fulfill this task also for longer periods even well as they can stabilize the grid with their capability of quick start/stop. However, their efficiency is limited and – even if burning climate neutral hydrocarbons – they still produce local emissions.

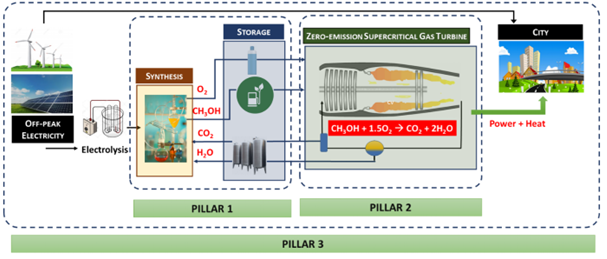

HERMES overcomes these limitations and advances gas turbine technology to the future-proof level by creating a reliable, flexible, zero-emission solution for energy supply with long term impact at EU level. HERMES develops and assesses the first highly efficient closed-loop supercritical zero emission energy system. It is based on directly fired supercritical gas turbine engine operating on locally synthesized renewable liquid and gaseous fuels (e.g. methanol or hydrogen) coupled with decentralized carbon capture utilization and storage (CCUS). The carrier medium is highly dense supercritical carbon dioxide or xenon demanding less compression power. Therefore, and because of operating at high pressure conditions (above 150 bar), the system achieves significantly higher efficiency (above 65%) than today’s gas turbines. By utilizing pure oxygen for fuel oxidation, and by capturing bulky flow of exhaust products (H2O and/or CO2) and reusing them for fuel synthesis, the system produces virtually no pollutants. A detailed assessment of the HERMES approach will be done using experimental and computational approaches and dynamic simulation tools including digital twins and machine learning.

The 36-month project is realized by an 11-partner consortium including 3 SMEs with expertise in renewable energy, combustion, techno-economics and socio-political science. Hermes will pave the way to a major breakthrough in the understanding of fundamentals of combustion in supercritical fluids with zero emission of any pollutants.

- ROGER - Integrated renewable energy systems for hydrogen production in congested transmission grids

Project description

Determining a sustainable hydrogen production technology integrated with wind and solar energy is critical to the growing interest in green hydrogen. Factors such as comprehensive analyses on the technical and economic variabilities, the impact of carbon pricing, optimum plant size, CO2 avoidance, logistics and storage are crucial to understanding the technical and economic sustainability of the potential green hydrogen technologies. Therefore, a comprehensive comparative technical and economic analysis of hydrogen production through different pathways is needed. Because of the integration of multiple energy sources and energy components, it is quite complex to match the energy systems with one another. Hence, optimal planning of integration of energy systems is essential to reduce the installation cost. This requirement can be met out by developing a combination of data-driven and digital twin dynamic models for analyzing the integrated energy systems for hydrogen and fuel production while preventing grid congestion. All aspects related to the dynamic behavior and optimization for the full emerging technologies and various form of energy flow scenarios will be considered in the model based on the available concepts that are designed in the integrated energy systems.

- System design and optimization of an electrolyser connected to a wind turbine

Wind energy is the fastest growing form of sustainable energy production and will continue to be very important in the energy transition in the coming decades. The continued growth of wind energy presents enormous technical, industrial and political challenges, especially in the storage of wind power during high production or low electricity consumption. Onsite production of hydrogen can be used for a variety of applications, including as transportation fuel and for generating electricity by using fuel cells or internal-combustion engine generators. The goal of this project is the system design of the integration of electrolysers and wind power. Different technical requirements will be addressed, such as wind turbine functional characteristics and physical limitations, installation of the electrolyser, Operations and Maintenance, and health and safety. Economic aspects also play a role, such as CAPEX and OPEX assessment revenues from electricity and hydrogen delivery. At the end the system will be optimized based on sizing, control strategies, integration of power-electronics, manufacturing and maintenance, hydrogen storage and transport, etc. The project cooperates with “ECN part of TNO”.

- Living lab for Innovative Future Environments

The operation of buildings has a tremendous impact on the world’s natural resources and the environment. Buildings are a major source of the pollution that causes urban air quality problems, and the pollutants that contribute to climate change. The solution to overcoming these problems will be to build them sustainable and smart to minimize the emissions and costs and to maximize the efficiency while increasing the comfort, health, and safety of the people who live and work in them. There will be a living lab, located on campus, consisting of three so-called tiny houses. The tiny houses use renewable energy sources such as wind and solar for energy production; fuel cells for energy conversion, and conventional battery, vanadium redox flow battery and thermal energy technologies for energy storage. They use also the option of converting electricity into hydrogen through electrolyzer in times of large electricity surplus due to overproduction from renewable energy sources. The tiny house project aims to develop, implement, optimize and test innovative configuration design operating on different energy carriers, such as electricity, heat and gas for the energy balancing to match and satisfy the end-user requirements.

- Smart Energy Grid in the Nijmegen Region

The aim of the project is to develop innovative strategies by developing powerful models and simulations to combine energy carriers such as electricity, heat, gas and fuels for heating and cooling of the built environment and industry, power and water consumption and transportation for the Nijmegen region. The model and innovative strategies include a comprehensive range of energy technologies and use large energy data sets in building and industry future scenarios to provide objective information for decision makers, in order to effectively design markets and regulations to support energy systems integration. The project is executed in close cooperation with a waste management company, SME, local government and startups as stakeholders of the future smart energy network. The pilot project will be implemented in the Nijmegen region for demonstration. In this project a proof of concept will be developed and validated which can then be further developed by participating SME companies to make a commercial software package.

- BOOSTing cross-border hydrogen in industry, research and education

The successful transformation to a sustainable energy supply requires the use of green hydrogen. In addition to importing the gas, however, large production capacities must also be built up nationally. To make the integration of electrolysers for the production of the versatile energy carrier hydrogen more efficient, an innovative software-based toolbox for electrolysers is being developed as part of the project. This enables companies along the green hydrogen production chain to digitally analyse, evaluate and optimise use cases in advance of real implementation. This toolbox is freely configurable so that components can be easily exchanged or adapted to simulate and compare different situations, plant designs or electrolysis processes (AEL, PEM, AEM).

Our role is leading the activities for developing a dynamic model for green hydrogen production plants. This involves integrating subsystems and balance of plant components, particularly focusing on the utilization of low-temperature electrolyzer technologies. Through detailed modeling, we will investigate the dynamic operation of these systems, ensuring seamless transitions between different operational states. Additionally, we will conduct parametric analyses at multiple levels, including the stack, sub-system, and system levels, to determine necessary measures to achieve predefined targets. Throughout this process, we will consider all relevant aspects related to dynamic behavior and optimization, including emerging technologies and various forms of energy flow, including heat and power, within the model. We will also contribute to interface the developed model with the toolbox.

In addition to the use of the tool in the context of project planning and in the business environment, the toolbox is implemented in the education and training of specialists. The consortium consists of companies with different competences in the field of hydrogen-based technologies and the integration of electrolysers, three universities with a focus on industrial research and experimental development as well as educational institutions for the training and further education of specialists.

- Energy hubs for the implementation of large-scale renewable energy

Increasing decentralized power production from wind and solar are putting a strain on the capacity electricity grid in different parts of the Netherlands. Consequently, new projects cannot be connected to the grid preventing growth of renewable energy production. Also, when power demand is exceeding the transport capacity, an extra alternative electricity flow is needed to fulfil the power demand. This could be solved by increasing capacity: grid expansion. However, this is expensive and takes years of time to be realized. Although grid expansion is inevitable in the long term, a solution is needed for a short/medium term. If the copper route is not an option anymore, then an alternative route through conversion to energy carrying molecules can be a solution. For this purpose we need major breakthroughs, advanced technologies and new integrated renewable energy systems for the energy hubs. Integrated networks of heat, gas and electricity systems with innovative energy conversion and storage technologies are required for the energy supply in our future cities, and without cooperation between very different stakeholders this transition will not be possible.

- H2-MODUS

Manufacturers of mobile machines such as sewer cleaners, excavators and generators have difficulty making their products more sustainable. Relatively high capacities and long operating times, in combination with limited access to electrical infrastructure at the location of use, make battery-electric solutions less suitable. Dutch manufacturers of mobile machines are therefore looking at hydrogen. Energy carrier hydrogen, produced from a sustainable source, offers the possibility of achieving greater power for a longer period of zero-emission through a fuel cell system on the machine and electrification of the drivetrain.

- High-Temperature Thermochemical Heat Storage Powered by Renewable Electricity for Industrial Heating Applications

HERCULES introduces a novel breakthrough approach towards thermal energy storage of surplus renewable energy via a hybrid thermochemical/sensible heat storage. The role of the heat storage on energy saving for industrial heating application will be explored in this project. In this project, our primary objective is to develop a comprehensive dynamic model for integrating thermal energy storage into high-temperature industrial processes. Our focus lies in enhancing flexibility within these operations by optimizing energy utilization, reducing operational costs, improving process efficiency, and bolstering resilience against supply disruptions. Ultimately, our contribution aims to foster more sustainable and resilient industrial operations through the seamless integration of thermal energy storage solutions. The proposed research will be conducted by an interdisciplinary consortium constituting leading research centers, universities, innovative SMEs, and large enterprises including ancillary service providers and technology end-users.

- A challenged-based learning community for hydrogen development and application

In the energy transition, two significant challenges arise: ensuring the availability of sustainable hydrogen as an alternative to fossil fuels and managing the increasing demand for and supply of electricity to prevent grid congestion. Decentralized production, storage, and application of hydrogen offer promising solutions to address both challenges. However, realizing this potential requires innovation and knowledge development. In the context of the RAAK SME project, companies and knowledge institutions, in collaboration with the hydrogen innovation center H2 Hub Twente, aim to develop expertise for the implementation of decentralized electrolysis systems. While these companies are actively working on offering system solutions for the decentralized electrolysis market, they still require further expertise in this domain. The primary objective of the project is to bridge the gap between theoretical insights and expertise on sub-aspects and the practical realization of well-functioning systems, along with identifying opportunities for improvements and innovations. To achieve this, the project focuses on the development and construction of a prototype electrolysis system integrated with the sustainable energy supply of H2 Hub Twente.

Research theme leader

contact person