PERFECT – Press forming without defects

2020-2024

Summary:

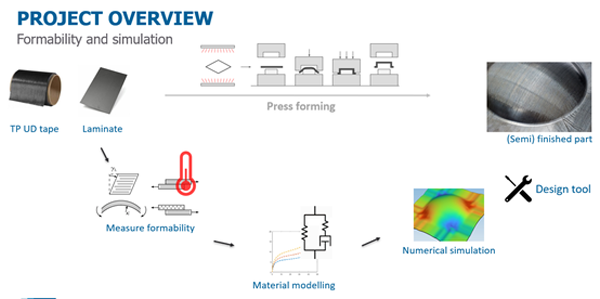

Press forming of continuous fiber-reinforced thermoplastics is an attractive manufacturing technology in the ongoing quest to use lightweight materials. Process simulation tools facilitate the design stage and the optimization of processing conditions with the ultimate goal to produce first-time-right composite parts without defects. The current level of simulation tools, however, do not fulfill the needs of industry, especially in case of unidirectional (UD) materials and more complex lay-ups and part geometries. Hence, advanced process simulations need to be developed to broaden the use of press forming in particular and to further promote the adoption of thermoplastic composites in general.

The PERFECT project aims to improve the reliability and detail of process simulations on defect generation through more advanced material characterization and modelling, including transient and thermal effects, and improved numerical implementations. In the end, the improved prediction quality will help industry to produce defect free parts of even higher complexity regarding shape and material.

PARTNERS: