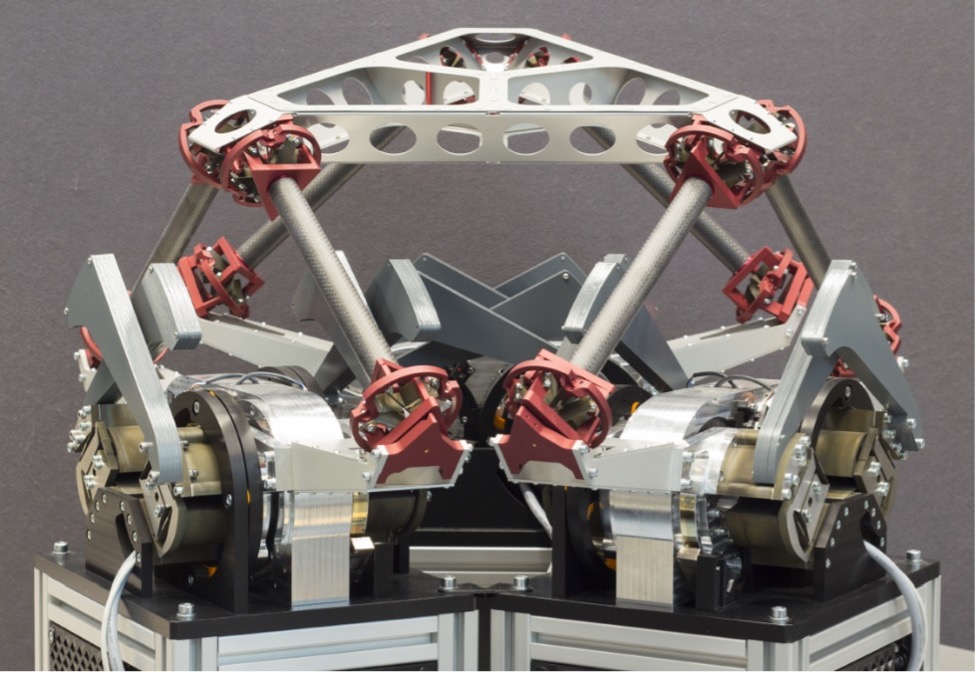

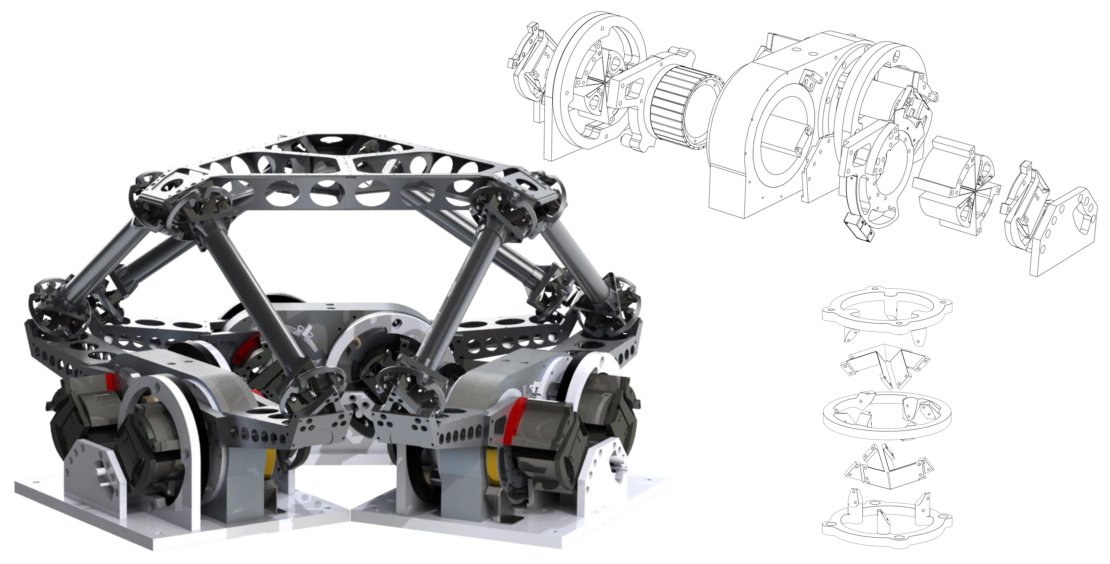

T-Flex: Fully flexure-based precision Hexapod

- 6 DOF with large range of motion

- Parallel kinematic structure for low moving mass and large accelerations

- Fully flexure-based joints for high repeatability

(no backlash, low hysteresis, no wear, no contamination) - Direct drive iron-core rotary motors (back-drivable, no backlash, no contamination)

- H2 feedback control to optimally reject amplifier's current noise

earlier footage

The footage above demonstrates the motion of the T-Flex (2021). The amplifier current is limited to about 10% of the maximum.

The footage above shows the 3D-printed test version of the end-effector, which has been replaced by an all-metal version in the final design. The controller is set to supply a constant drive force to statically obtain the neutral platform position. Note the low natural frequency and damping in the degrees of freedom. The internal vibration mode frequencies (mode 7 and higher) are about a factor of 30 higher than the ones in the degrees of freedom. The damping is mainly originating from the torque motor and its driver.

Specifications

Dimensions: 840x840x400 mm

Translational workspace: volume of 5 liter with inner cube of 100x100x100 mm

Translational travel range* x, y, z (with z the vertical axis): +/-100 mm (100 mm bidirectional)

Rotational travel range* Rx, Ry, Rz (with z the vertical axis): +/-15 degrees (15 degrees bidirectional)

*The travel range given is the maximum travel, with all other axis remaining at their neutral position

Repeatability: 50 nm

Load capacity: 10 kg

Acceleration: 5-10g (for small payloads)

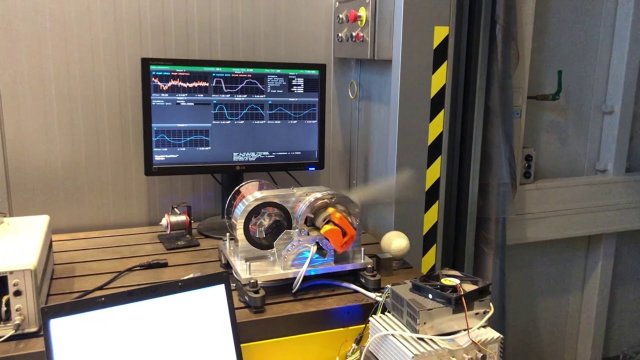

Flexure-based high -torque iron-core motor suspension testing

This video shows the modified butterfly hinge design of the iron-core motor suspension with the slaving mechanism. The low hysteresis of the flexure-based design is demonstrated.

This video shows some initial controller tests of the high-torque direct-drive motor with the flexure-based suspension.

Scientists involved

Related publications

M. Naves (2021). Design and optimization of large stroke flexure mechanisms, PhD thesis, https://doi.org/10.3990/1.9789036549943.

M. Naves, M. Nijenhuis, B. Seinhorst, W.B.J. Hakvoort, D.M. Brouwer (2021). T-Flex: A fully flexure-based large range of motion precision hexapod, Precision Engineering 72, pp. 912-928. https://doi.org/10.1016/j.precisioneng.2021.08.015.

M. Naves, M. Nijenhuis, W.B.J. Hakvoort, D.M. Brouwer (2020). Flexure-based 60 degrees stroke actuator suspension for a high torque iron core motor, Precision Engineering, Volume 63, pp. 105-114. https://doi.org/10.1016/j.precisioneng.2020.02.001.

M. Naves, R.G.K.M. Aarts, D.M. Brouwer (2019). Large stroke high off-axis stiffness three degree of freedom spherical flexure joint, Precision engineering, Volume 56, pp. 422-431. https://doi.org/10.1016/j.precisioneng.2019.01.011.

M. Naves, D.M. Brouwer, R.G.K.M. Aarts (2017). Building block based spatial topology synthesis method for large stroke flexure hinges, ASME robotics and mechanisms, 2017, doi: 10.1115/1.4036223.

Acknowledgement

This research was part of the VIDI project 'Large range of motion spatial flexure joints', a personal grant of Dannis Brouwer, funded by the Innovative Research Incentives Scheme VIDI (14152 NWO TTW Toegepaste Technische Wetenschappen) of the Ministry of Education, Culture and Science of the Netherlands.