Duration

Start: 01-12-2011

End: 30-11-2014

Partners

Netherlands: Philips Consumer Lifestyle, TNO, Science & Technology Corporation, VSL

Germany: FAU Erlangen-Nürnberg, BIAS, Siemens AG, Technische Universität Hamburg-Harburg, Precitec KG, BIMAQ, University of Bremen, VEW

Switzerland: ETH Zürich, E. RIHS AG

Belgium: Noesis Solutions

Russia: Siemens OOO

Staff

- prof.dr.ir. Ton van den Boogaard

- E.P. Roux

- dr.ir. G.T. Havinga

Description

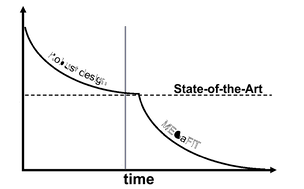

The goal of the MEGaFiT project is to reduce the amount of defects in manufacturing of complex high-precision metal parts. Nowadays robust design optimization strategies are applied to achieve better production accuracy. However, active control of the production process variations is needed to get beyond the current state-of-the art production accuracy.

Metal forming processes may have a large amount of parameters which influence the final geometry of the product, such as material properties, temperature, friction, tool alignment and tool wear. Variations of these parameters cause variations in the geometry of the product. The challenge for accurate production is based on dealing with these process variations.

Within MEGaFiT the approach for tackling this problem is to design a feedback-loop in the production process. Every product which comes from the production line is measured with an optical system. The geometrical deviation with reference to the desired geometry is analysed. This information is used to actively control the production line, resulting in a decreased amount of erroneous products.

The determination of the optimal process settings are based on process knowledge which is gathered through finite element modelling of the process. The knowledge obtained through individual finite element simulations can be used to construct metamodels of the process, obtaining a fast tool to predict the behaviour of the process anywhere in the parameter space. These metamodels can then be used to determine the optimal control strategy.

The Applied Mechanics group contributes to the MEGaFiT project with knowledge and research in the fields of metal forming, material modelling, finite element modelling, robust optimization and metamodeling.

MEGaFiT is an European Project, funded by the Factories of the Future program of the European Commission’s 7th framework program.