Duration

Start: 01-12-2009

End: 29-11-2013

Partners

![]()

![]()

![]()

![]()

![]()

Staff

- ir. J.H. Wiebenga

- prof.dr.ir. Ton van den Boogaard

Introduction

The majority of engineering problems and manufacturing processes encountered in practice are subject to multiple sources of scatter, e.g. fluctuating process settings, changing environmental conditions, varying material properties, etc. As a result, product quality will show fluctuations as well, possibly exceeding quality requirements and leading to product failures.

Challenge

The challenge is to design robust forming processes, i.e. processes that are insensitive to these inevitable sources of scatter. The goal of this research is to integrate robustness in the numerical design and optimization process. This is achieved by coupling Finite Element simulations with a robust optimization software developed at the University of Twente. Developments are focused on efficiency since computationally expensive FE simulations are generally used.

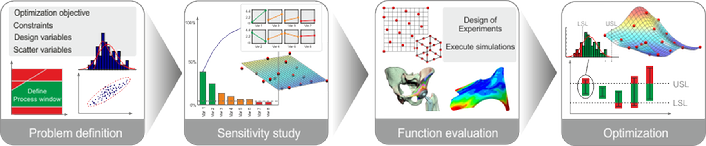

Figure 1: Robust optimization strategy

Results

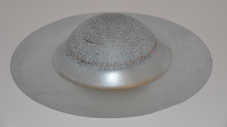

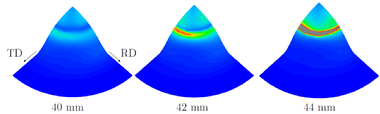

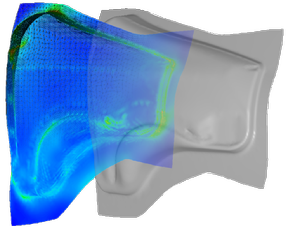

A robust optimization strategy and software is developed, see Figure 1. The four step approach can be applied in all stages of the design process, from initial robustness prediction in the early stages of process design to trouble shooting during production. It assists in predicting product failures caused by e.g. variation of material properties, see Figure 2. Moreover, the optimal process design and settings can be determined such that the deteriorating effects of process variation during production are limited to an acceptable level. The resulting robust forming processes will exceed initial expectations on quality level and produce products of constant high-quality.

Figure 2: Application to metal forming processes: Example cup product (left) and a car side front member