Development of a maintenance-based use policy and application to HNLMS Johan de Witt

Gert-Jan Smit - Koninklijke Marine (December 2022)

SUMMARY

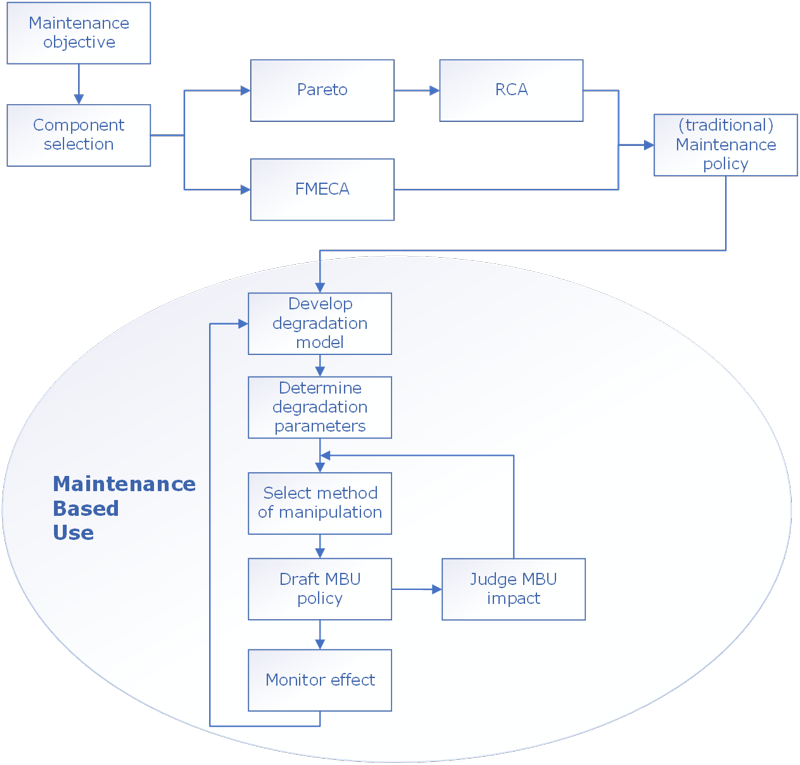

Up until now, most maintenance policies have focussed on planning maintenance around the use of a system. However, in certain circumstances, it is advantageous if maintenance only needs to be performed at certain time intervals. For these cases, a Maintenance-Based Use (MBU) policy has been proposed in which the use is adapted (slightly) in such a way that a maintenance objective/interval is met. Doing this can potentially combine high system availability with minimised financial cost and maintenance facility usage. The proposed MBU policy can be seen below.

Figure 1: Proposed Maintenance-Based Use policy

At first, the ‘critical’ components – that influence maintenance efforts severely - are selected. For each of the critical components, a degradation model is developed that links the degradation to the use. From the degradation model, the degradation parameters are extracted. These are the parameters that influence the degradation. Most of the degradation parameters have one or more methods in which they can be manipulated to change the degradation behavior. Of these methods, one or a few must be chosen and implemented, such that manipulating them has the least impact on the use. In basic form, this is a MBU policy. However, adding a feedback/monitoring loop will increase the reliability and accuracy of the whole policy.

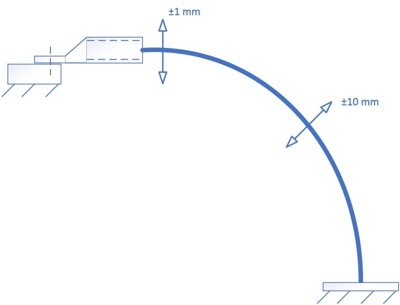

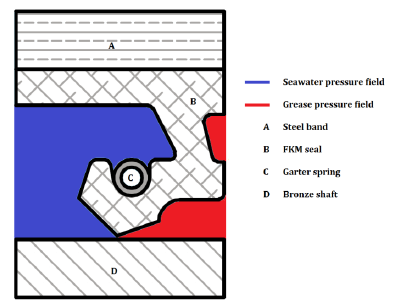

The MBU methodology has tested on two critical components of a naval system: a cable lug of the propulsion system (Figure 2) and a propulsion shaft seal (Figure 3) to investigate whether the MBU policy will ensure a lengthened maintenance interval.

Figure 2: Sketch of cable installation and vibration mode (cable lug is top left)

Figure 3: cross section of drive shaft and seal

KEY RESULTS

1. For the first case study, not enough information was available to come to a quantitative result. On the other hand, it is expected that avoiding certain propulsion speeds will reduce degradation due to reduced vibration frequency and amplitude. Determining the precise RPM ranges will need further study.

2. For the second case study, changing the seal grease pressure from minimum to maximum is expected to decrease the wear rate (and thus increase time to failure) by 30%.

3. Both case studies show a strong possibility that adapting the use of the system results in slowing the degradation of the component significantly, allowing an increased maintenance interval. These adaptations can be chosen in such a way that the impact on the system and its use is minimal. This proves that the proposed MBU policy can be effective in ensuring a system will stay operational over a set maintenance interval.

4. To determine the effectiveness of Maintenance-based use, it is advisable to apply the MBU policy to a component/system and monitor if the predicted effects are achieved over a longer period of time.