Education in the CDSM group includes Courses and Assignment projects in the field of Mechanical Engineering (ME).

Courses

Courses from the CDSM group are given at Bachelor and Master levels. An overview of the required steps to complete the administrative process of a Bachelor's or Master's Programme in Mechanical Engineering (ME) can be found here (Bsc) and here (Msc).

BACHELOR COURSES

MASTER COURSES

Please find updated and more detailed information about these courses on OSIRIS

MASTER ASSIGNMENTS

The master assignments offered by the CDSM group center around the mechanics of materials and computational analysis, spanning a diverse range of applications from artificial materials like elastomer composite materials filled with nanofiller, recycled fiber-reinforced polymer composites, metals, and 3D-printed materials, to natural bio-materials such as bones and teeth.

If you are seeking an assignment in the field of computational design of structural materials, we strongly recommend reaching out to us for personalized guidance:

prof.dr.ir. I.M. Gitman (Inna)

Full Professor

Finished MASTER Projects

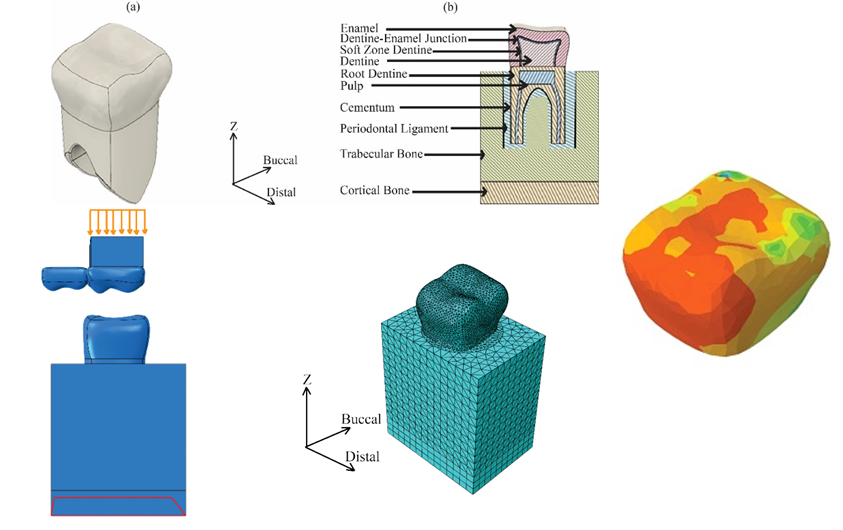

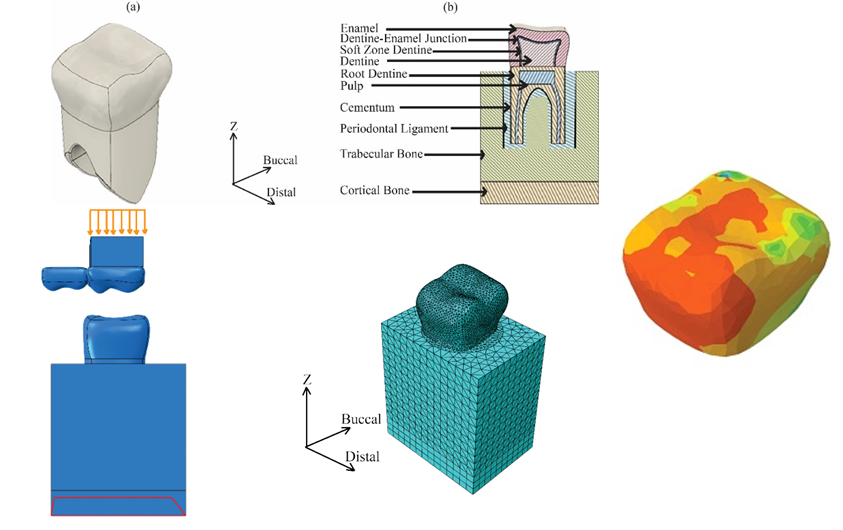

Importance of model parameters in teeth stress analysis (Nikolas Stratis, MSc project) Aim: to investigate the effect of internal tooth structure, material properties and loading conditions, have on the stress state

Finite element modelling is the commonly used methodology for the analysis of stress concentration within tooth components. The main limitation of the technique is that over-simplifications are usually required due to the complex conditions at which oral structures operate. Therefore, the aim of this study is to examine how assumptions and modelling practices, related to the internal tooth structure, material properties and loading conditions, affect the mechanical response within dental models. This was achieved by developing a generalised mandibular first molar tooth model and by performing an in-silico parametric study.

Modelling spot-welding in high strength automotive steel (Mr Hanting Xiao, MSc project) Aim: to investigate the behaviour of spot-welded sample of Dual Phase 1000 steel where heat affected zones in the weld have varied microstructure and hence varied mechanical properties

Weight reduction in car body is becoming increasingly demanding in the current automotive industry. Stronger and more light-weighing materials are desirable because they help improve vehicle efficiency and compliance to low-carbon regulations. Advanced High Strength Steel (AHSS) is capable of meeting those requirements since this group of material shows both high strength and good formability. Higher strength leads to better crash performance and allows weight reduction using thinner parts, while formability is essential for mass production. The current study focused on Dual Phase (DP) 1000 steel, which is applied in safety critical body parts such as B-pillar and bumpers of a car.

Resistance spot welding is a major joining technique for mass production in the automotive industry. Its advantages include short cycle time, high automation rate and low cost. The welded part is divided into three zones: fusion zone (nugget) in the centre, heat affected zone (HAZ) around the fusion zone, and base material (BM. The mechanical properties of AHSS are negatively affected by sudden heat transfer and cooling during welding process. Therefore, it is desirable to study the behaviour of spot welded AHSS.