An energy-efficient campus

In the course of running our daily operations, our university uses energy. Although allowing our primary processes - education & research - to continue unhindered at all times is paramount, we work hard to minimize the impact of our energy use on our environment and climate. We do so through the Trias Energetica: firstly, we focus on minimising our energy demand; secondly we use sustainable energy where possible, and thirdly, when that's not possible (yet) we use fossil fuels as cleanly and efficiently as possible.

In the course of running our daily operations, our university uses energy. Although allowing our primary processes - education & research - to continue unhindered at all times is paramount, we work hard to minimize the impact of our energy use on our environment and climate. We do so through the Trias Energetica: firstly, we focus on minimising our energy demand; secondly we use sustainable energy where possible, and thirdly, when that's not possible (yet) we use fossil fuels as cleanly and efficiently as possible.

PLANNING

Click to zoom in

More about energy

Trias energetica

The Trias Energetica is the starting point for all energy consumption at the UT, which involves limiting the demand for energy, using sustainably generated energy and looking at energy consumption throughout the chain (suppliers of the UT).

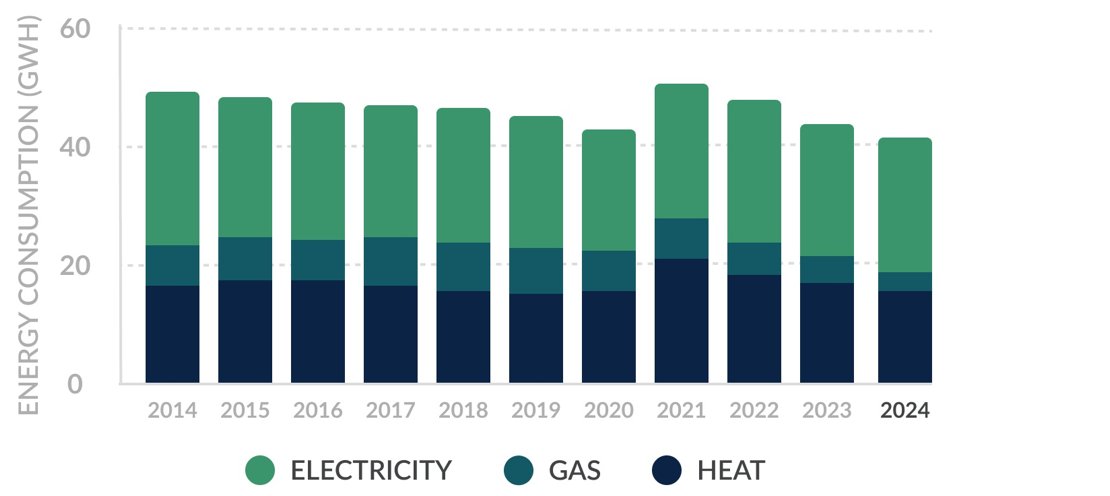

Energy consumption at UT

The graph below shows the campus’s energy consumption from 2005 to 2021. The consumption of electricity, natural gas and district heating has been translated into Gigawatt hours (GWh). There was a long-term agreement with the Dutch government to cut energy consumption by 30% over the course of 15 years. We achieved the target consumption levels that were set for 2020 as early as 2014. Since then, energy use at the UT has continued to decline, with an uptick during the Corona crisis due to continual ventilation of UT buildings.

Until now, energy saving measures have focused mainly on making the buildings more energy efficient. Users, however, can also influence energy consumption. To continue the downward trend in energy use, the next step includes involving employees and students on the campus, so that people will become more conscious of how they use lighting, heating and cooling systems, as well as all other devices.

Energy generation on campus

The Technohal, where the TechMed Centre is housed, features 624 solar panels on the roof. The recently renovated Langezijds building, where the ITC faculty is located, features 916 panels. An additional 120 solar panels are located on the roof of the Oosthorst and 77 panels are located on top of Drienerburght. Finally, 69 solar panels are located on the SlimPark Living Lab. In 2023, these panels (then still without Langezijds) produced approximately 207.000 kWh, or 1% of the total electricity usage of UT buildings.

Solar panels on Langezijds

The outdoor swimming pool of the UT is heated by 40 solar collectors. The Sports Centre boasts two solar water heaters with a combined output of 52 GJ per annum. Gas-fired supplementary heating - amounting to 1280 m3/year, which is comparable to the annual energy consumption of a single household - is used to meet the entire heating demand.

Suppliers

Since 1 january 2022, the UT's electricity is supplied by Engie and is 100% green. Per 1 october 2022, gas is supplied by Vattenfall. District heating is supplied by Ennatuurlijk.