Duration: 2023-2027

Funding: NWO - Perspectief

ABOUT THE PROJECT

Dutch circularity goals 2030 and 2050 have been set to increase sustainable practices. Steel industry is already taking step in this regard by recycling the scrap steel. But, the obstacle in achieving full circularity is that the scrap cannot be used to produce high quality steel used for battery and automotive applications.

In addition to steel composition, we can improve steel quality by manipulating its thermomechanical history according to the scrap. One way to achieve this is use of computational models which can map the (i) steel properties to thermomechanical processes and (ii) thermomechanical processes to process settings. Such types of models are already being used in the industry but they are not very fast and accurate. To resolve this issue, the latest approach is combining process data with the model. This leads to the project “”Data Enhanced Physical Model to Reduce Material Use” or DEPMAT.

DEPMAT is further divided into five work packages (WPs). Second work package (WP2) is called “Hybrid process models for indirect inline measurements” and this project is the first in this package, hence WP2a. It is aimed at prediction of material properties of the steel so that this information can be used to tune the process settings to get desirable quality. This will be achieved by developing a hybrid model of the cold rolling process.

Goals

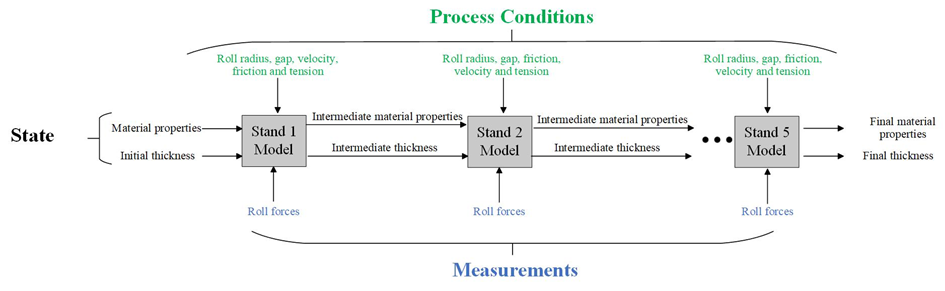

1. A hybrid model for cold rolling will be developed to determine final material properties. In this model, process state (material properties and sheet thickness) will be improved using process measurement process and then passed to the next stand until we get the final state.

2. A simple material test and inverse analysis procedure will be designed for the steel end user to obtain its properties. In this way, steel end user does not depend on steel supplier for material properties data. Further, tensile test can provide reasonably accurate information about material properties but often approximate information is sufficient to determine process settings. So, a simple test and procedure can replace tensile test.