Identification of damage precursors in 3D-printed aluminium alloy after fatigue testing

Kasper van Loobergen – UTwente internal (April - December 2019)

Thesis: https://essay.utwente.nl/80352/

SUMMARY

Previous work has indicated that damage precursors can be a promising method for predicting and preventing fatigue damage in metal structures. Test plates made from Scalmalloy (an aluminium alloy) were printed using Selective Laser Melting and subjected to fatigue experiments as part of previous research in order to detect damage precursors based on dynamic properties. The work for this assignment consisted of analysing the physical properties of these plates after they had been subjected to fatigue loading in order to find the cause of the previously measured changes in dynamic behaviour. A batch of test plates made from conventionally produced Al7075-T6 were used as a reference.

A number of approaches to define damage precursors were discussed. Material characterization tests were carried out to help understanding the link between change in dynamic behaviour and physical material changes, since this is essential for properly understanding dynamic damage precursors. Methods that were used to analyse physical properties of the test plates include optical microscopy, confocal microscopy, density analysis, CT-scanning, micro- and nano-indentation and EBSD-analysis. The main cause of the previously observed change in dynamic behaviour can be traced back to early stages of fatigue crack growth, but the applied analysis methods did not indicate significant change of material properties before the first fatigue cracks started to appear.

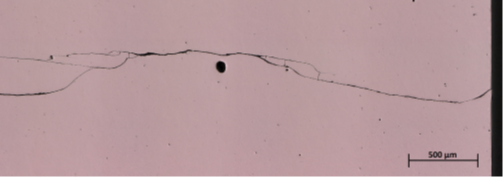

(a) Before polishing

(a) After polishing

Figure 1 Microscope images of cracked area before and after polishing (432.750 load cycles).

Also, some attention is given on how damage precursors could be implemented to improve maintenance policies and increase reliability of systems, and what the limitations of damage precursors are in practical applications.

KEY RESULTS

- Early fatigue cracks could be visualized successfully with optical microscopy and appeared earlier than expected based on dynamic measurements in the past.

- Polishing improved visibility of cracks and made porosity in printed material apparent.

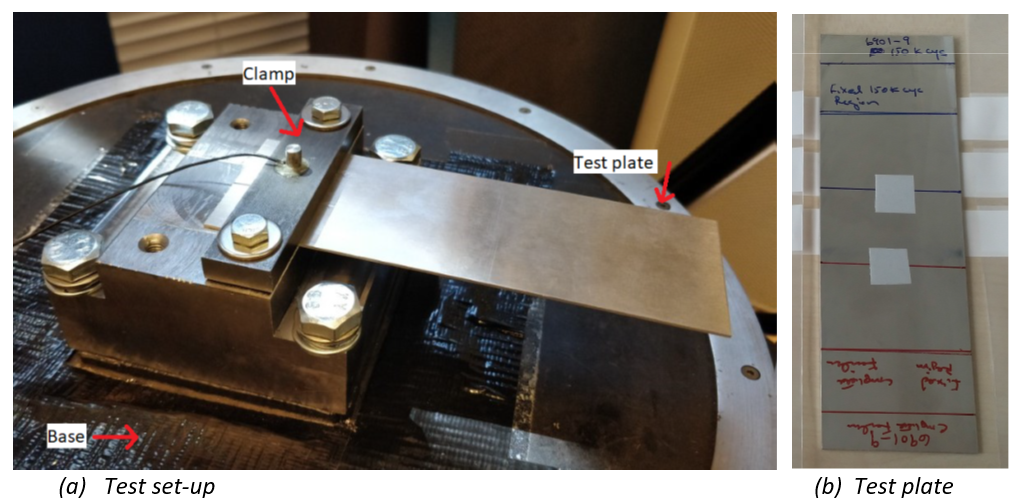

- Fatigue cracking of the test plates was influenced substantially by the clamping mechanism that was used during fatigue experiments.

- No evidence was found that the small amount of porosity present in the Scalmalloy samples had a major influence on crack growth.

- No major change in mechanical properties of Scalmalloy and Al7075-T6 was found close to existing fatigue cracks.

Figure 2 The test set-up that was used to apply fatigue load in previous research and one of the test plates that were analysed in this work. The base was vibrated in the eigenfrequency of the freely vibrating end to apply a fatigue load.