Stefan Oosterik – University Twente (November 2013 - November 2014)

SUMMARY

The development of advanced monitoring systems enables placing sensors on the blades of rotating blade system, such as the main rotor of a helicopter (Fig. 1). On-blade vibration monitoring can be used to reduce this uncertainty and provide additional on-blade data (e.g. blade strain data). However, the response of a rotating blade system remains complex and a successful rotor monitoring system has to be capable of coping with this complexity. Therefore the development of advanced monitoring systems (wireless, on-blade sensing) starts with a concise understanding of the dynamic behaviour, the influences of different operational conditions and possible failure/damage scenarios.

Figure 1 Helicopter main rotor

Figure 2 Function-Behaviour-Structure framework for monitoring

The first part of the research is concerned with identification of the (sub-)functions , components of the structure and the physics covering the helicopter rotor behaviour. The case study is limited to a articulated (hinged) rotor blade in hover flight. In the next part, the complexity of the behaviour of the helicopter rotor blade is studied using a physics based model. Moreover, the implications for vibration monitoring are identified. The final part involves the effect of a specific damage scenario on the behaviour of the helicopter rotor and the possibility of detecting the damage on-flight.

KEY RESULTS

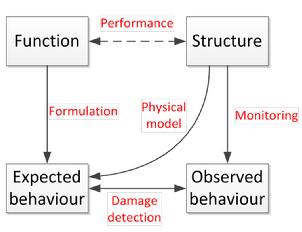

- •A framework for monitoring of complex systems (see Fig. 2)

- •A physics based model that describes the behaviour of a helicopter rotor blade in hover flight

- •It is shown that both rotation (see Fig. 3) and aerodynamics affect the dynamic characteristics of the rotor blade

- •The possibility for detecting local blade cracking on a free rotating blade is demonstrated, using both global and local methods

- •The implication of the rotor complexity on damage detection and performance monitoring are shown

Figure 3 Campbell graph for case study blade with