Within CPM we focus on four fields of research: Activiation of Stable Molecules, Catalysis in Liquid Phase, Green Fuels and Biochemicals, and Multi-scale Modelling.

Activation of Stable Molecules

Activation of stable molecules, which is either caused by thermodynamics (e.g. N2, CO2 and H2O) or because of kinetic reasons (e.g. methane) with catalysts as well as via plasma catalysis is being studied. Also, catalytic membrane reactors are studied for driving conversion that are equilibrium limited, e.g. dehydrogenation of ethane and propane. Selective oxidations reactions have been studied as well, e.g. by using stable compounds like CO2 and H2O as soft oxidants.

Catalysis in liquid phase

Concentration gradients are frequently present when applying heterogeneous catalysts in liquid phase because of relatively slow diffusion. The consequence is loss in performance and/or falsification of kinetic information. Therefore, we synthesize and test new structured supports that suppress gradients in and around catalyst support materials. Responsive polymers are explored to tune the rate of transport, whereas in-situ characterization of catalysts in liquid phase is used to gain understanding. Image on the left shows super-porous catalyst supports based on Carbon Nano Fibers.

Green Fuels and Biochemicals

Bio-derived feedstocks are a renewable source of C and H that can serve as building blocks to create plethora of fuels and chemicals. The challenge in this case is that heteroatoms (e.g. O, N, and S) and the presence of water in their structures complicates their chemical conversion as these species can deactivate catalysts readily. In our group we develop new catalysts that can selectively valorise the bio-based feedstocks without undergoing fast rates of deactivation. We employ detailed reaction kinetics and catalyst characterization to pin-point the cause of deactivation and create new materials that can operate under these harsh reactive environments

Multi-Scale Modeling

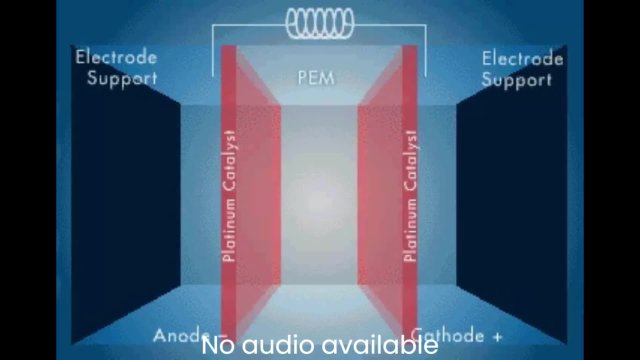

We employ a hierarchical approach to accurately predict the performance and lifetime of commercial-scale systems directly from material, catalytic and morphological properties measured in the lab. We combine a myriad of modelling methods including detailed micro-kinetic surface reaction modelling, mesoscale structural evolution modelling, continuum transport modelling, flowsheet modelling and machine learning to work towards increasingly higher fidelity digital twins for design and control. The image on the left shows a 3D rendering of a membrane.

For more information you can visit the SEED website.

For more information you can visit the CPM research database and the IM research database