project information

Full title: | Recovery of minerals and fuels from paper sludge via flash pyrolysis |

Acronym | Pyrolysis Paper Sludge |

Funding/Programme | - |

Duration | 2017-2019 |

Partners | Alucha |

project description

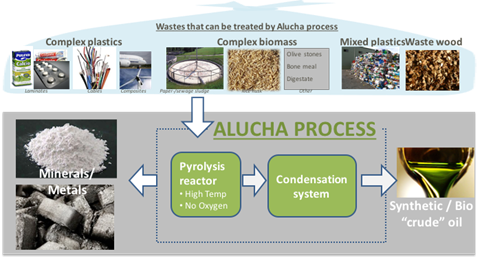

At its workshop in Arnhem, Alucha is currently developing a 100 kg/h mobile container unit to treat and recycle paper sludge. Paper sludge is the largest waste stream in the paper industry. The waste stream is produced by the water treatment plants in paper mills. Currently there is no sustainable solution to treat this waste stream. With the new advanced pyrolysis technology, they aim to recycle the minerals (such as Kaolin, calciumcarbonate) in the paper sludge (about 50% of the stream). The other 50% consist of paper fibers that will be converted into bio-oil.

The EngD project will consist of modelling and optimizing the pyrolysis process for further upscaling. The patent pending reactor has now been designed for 100 kg/h capacity. The project consists of developing a CFD model for the reactor. The results from operational tests with the pilot plant during 2017 can be used to verify and validate this CFD model. The EngD trainee can participate in these tests together with the Alucha team. Based on this validation, the reactor can be further designed, improved and finally upscaled to 1000 kg/h. Next to reactor design, the optimization of the energy efficiency of the pyrolysis process will be part of the project.