Duration: 2022-2026

Funding: TKI

ABOUT THE PROJECT

Nowadays, automotive and packaging industries requirements on strip surface texture are becoming increasingly stringent. Surface texture determines the perceptual appearance of the strip surface and its tribological behavior. To control these properties, it is necessary to predict strip surface texture based on process parameters. The theoretical/experimental methods developed to predict and control the strip surface roughness so far are generally limited to either empirical models originated from a database of roughness measurements or oversimplified physical models. These models typically hand in a scalar number such as average roughness without providing any indication on spatial and functional parameters of the strip surface. This is mainly due to lack of knowledge on fundamental physical aspects of surface deformation and roughness transfer during cold rolling process.

Goals

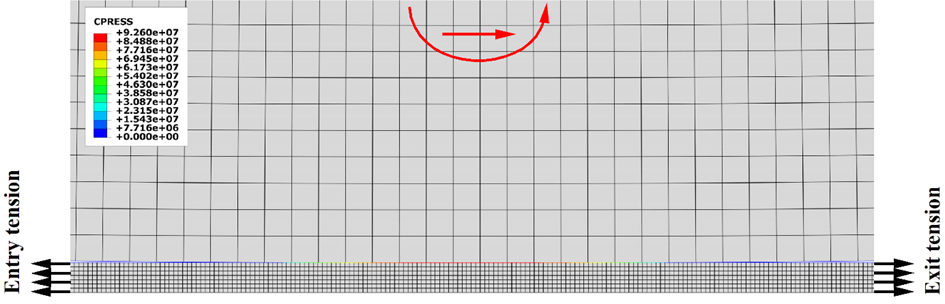

The goal of this project is to understand the fundamental physics of the roughness transfer during rolling process and identify determining physical phenomena which take place at micro-scale (asperity scale) and macro-scale (roll-bite contact). The knowledge enables to develop physical roughness transfer models in order to predict the final surface texture of the strip based on process parameters (roll radius, rolling load, strip tension, etc.) and process variables (strip material behavior, roll and strip initial surface configuration, lubricant amount, etc.) during cold rolling processes.