29 / 03 / 2021 | Hans Wolkers Utoday - https://www.utoday.nl/science/69688/plastic-membranes-for-cleaning-water-and-more

‘Plastic is known to pollute our oceans and water, but in in this case it is used to clean water. I think that’s great!’ says Wiebe de Vos. Together with his colleagues Saskia Lindhoud and Ameya Krishna, the UT membrane scientist developed a sustainable and easy way to produce a membrane based on a novel plastic. It’s use is versatile, and making drinking water is just one of the many possible options.

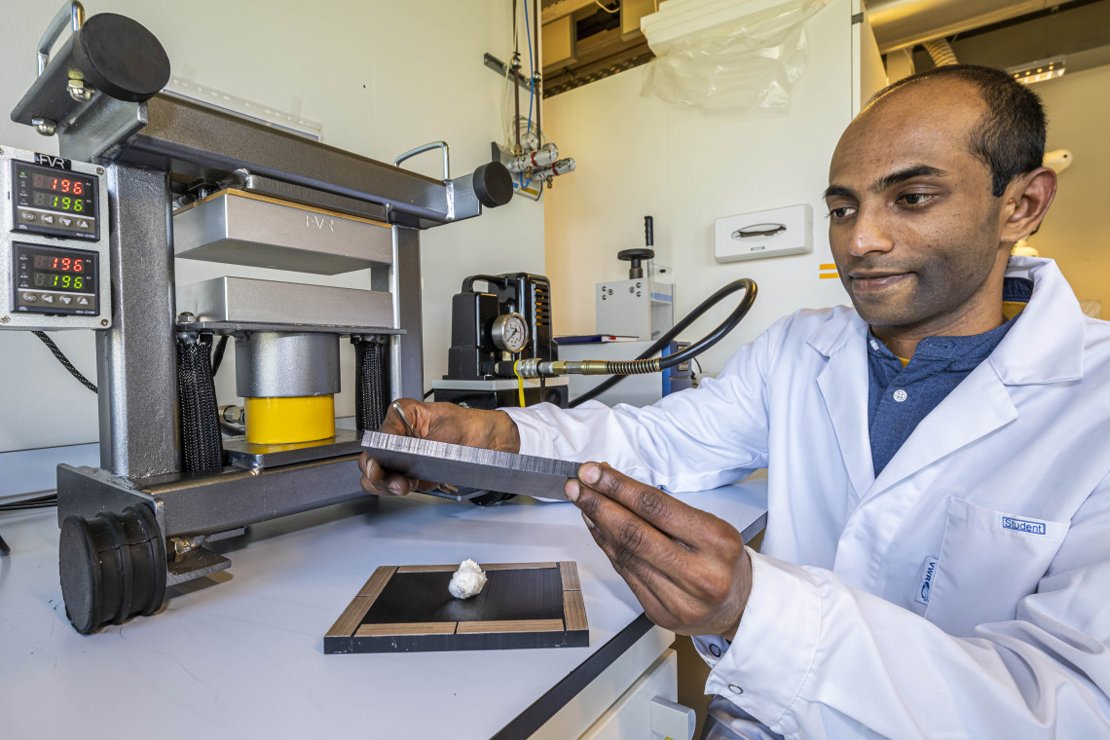

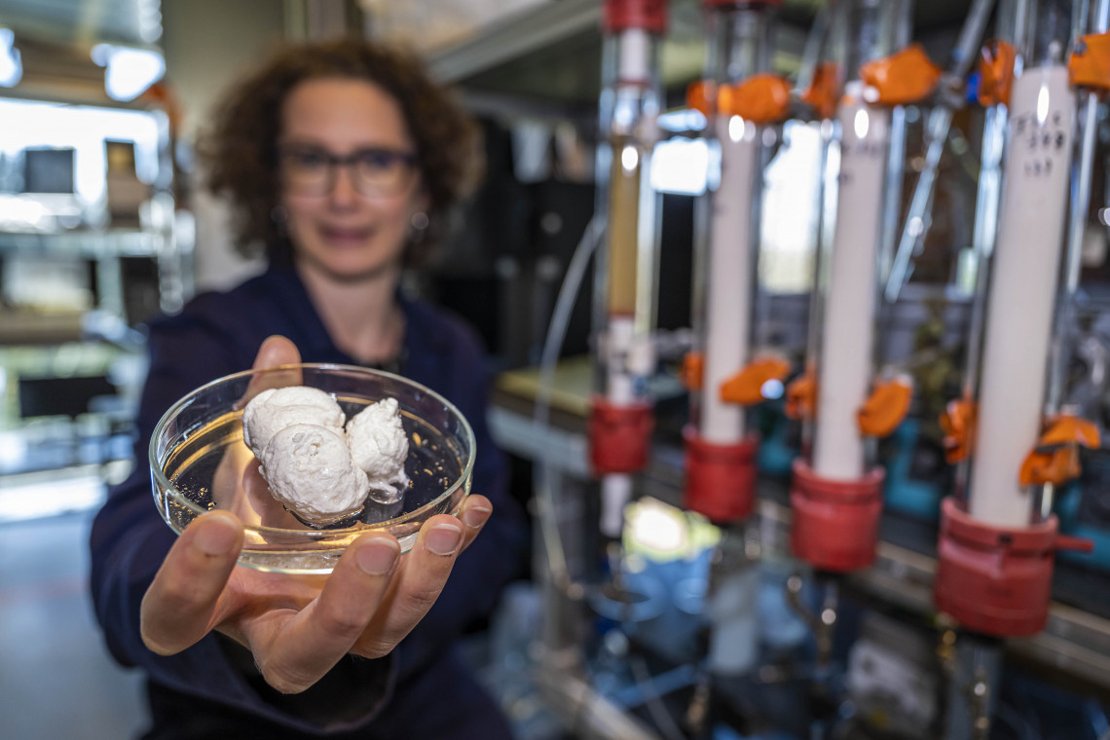

Using tweezers, PhD researcher Ameya Krishna (UT Faculty of Science and Technology) picks up a white, round piece of an amorphous, mozzarella-like substance, and sandwiches it between two aluminum plates. Then he places the plates in some kind of press, resembling a sandwich maker, and flattens the ‘mozzarella’.

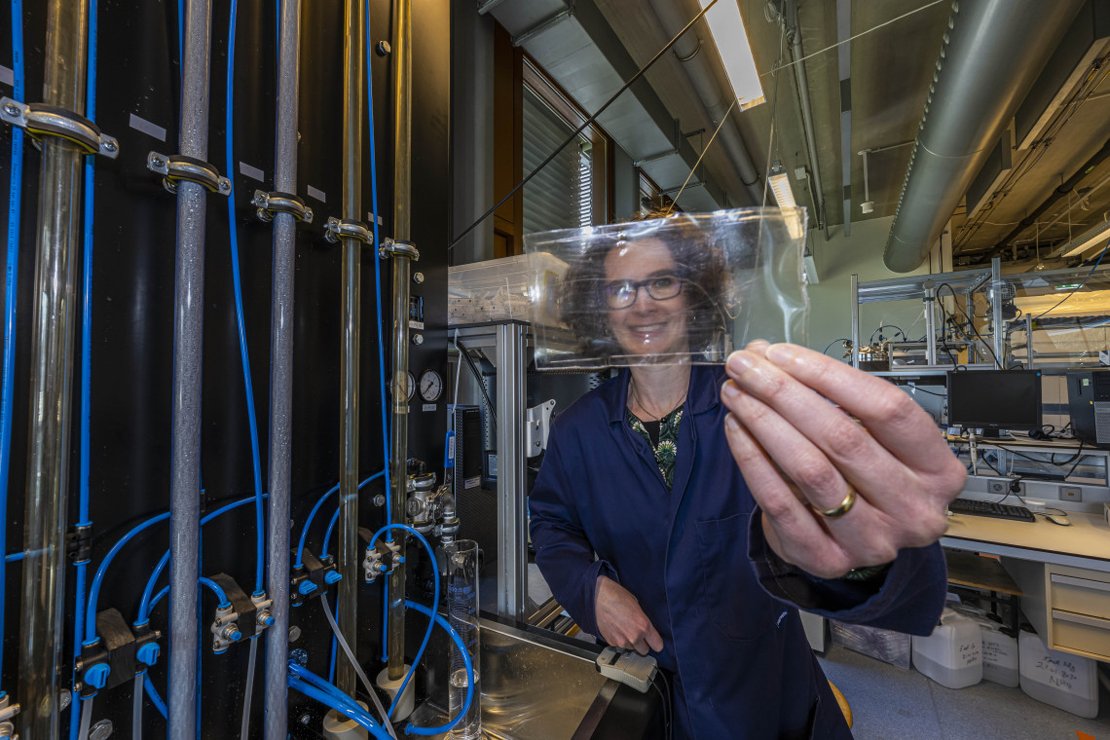

‘We bring the temperature to 80 °C, and wait until the mass has flattened,’ Krishna explains the process. ‘Then we increase the pressure to about 200 bar and the materials properties will slowly change.’ Red and green lights blink, indicating the impressive force that is put on the material. After about an hour the scientists opens the press. The ‘mozzarella’ has transformed into a flat piece of transparent plastic, called a saloplastic. Despite its simple appearance, this plastic is special and can be used as a membrane with many different applications.

Plastic sheet

Membranes are essential in many different industries. They play, for example, a crucial role in removing contaminants from wastewater, while in arid countries, they are applied to desalinate seawater for drinking water production. In many industries membranes are also widely applied in a variety of processes, from the storage of energy, in the so-called electrical fuel cell, to the sterilization of food, without heating.

‘A membrane is a plastic-like sheet containing many tiny pores, kind of similar to a filter,’ explains De Vos. ‘Depending on the pore size and the membrane material, some substances are stopped, while others can pass through the pores.’ Using these properties, membranes are used to filter bacteria or even viruses out of water. In wastewater treatment, membranes with even smaller pores are used to remove medicine residues. But membranes can also be designed to stop all substances, except water. These membranes are common in water desalination plants, where seawater is forced through the membrane under high pressure: reverse osmosis. Only the water can pass, while the dissolved salts are retained. Especially when the salt concentration is high, like in seawater and some industrial wastewaters, reverse osmosis is very efficient.

Ion-exchange membrane

However, if salt concentrations are lower, like in brackish water, these pressure-driven membranes are not so efficient, since a lot of water has to be pressed through the membrane while relatively little salt is retained. For these conditions, another type of membrane, a so-called ion-exchange membrane, is used. These membranes remove charged particles, like atoms and molecules, from water utilizing an electric driving force. For example, water containing dissolved salt can be desalinated when an electric field draws positive salt ions, like sodium (Na+) through one membrane and negative salt ions like Chloride (Cl-) through another, while the water remains. However, production of such membranes is complicated and expensive. In addition, very acidic or alkaline conditions may damage the membrane, making them unsuitable for applications in the chemical industry where harsh conditions often occur.

More resilient

The discovery of the new saloplastic membrane by the UT scientists was partly coincidental. In their search for a better membrane to remove medicine residues from wastewater, De Vos and his team were trying to improve these traditional, pressure-driven membrane by coating them with thin layers of alternating positively and negatively charged polymers. Polymers are long molecules that form the building blocks of plastics.

The scientists managed to improve these membranes by adding thin polymer coatings. They also discovered that these coatings were highly resilient to acidic or alkaline conditions. The idea was born to try to construct a completely new membrane using a mix of these positively and negatively charged polymers only. The procedure to make plastics from these so-called poly-electrolyte complexes was already known, but it was difficult, energy-and time-consuming, while they were never used as a membrane.

Eventually, the scientists managed to develop a spectacularly simple and cost-effective method. They first dissolved the positively and negatively charged polymers in water, and these quickly formed this insoluble rubbery, mozzarella-like mass. After the hot press treatment, this resulted in a transparent, plastic membrane. De Vos: ‘The heat and pressure helps to bring the opposite charges of different polymers together in an even way, forming a transparent plastic sheet. A big advantage is that the process is suitable for bulk production.’

Reuse

The deceivingly simple-looking plastic has some amazing properties. It functions as a stable and effective ion-selective membrane, where differently charged ions can pass or are retained, depending on the polymers used. It is therefore suitable as a cost-effective desalination membrane, but it can also be used to soften water by removing calcium or sulphate ions. Due to its resilience against extreme acidity or alkaline conditions, it can also be applied in various chemical processes. And recycling the plastic is simple. Because the polymers are held together by opposite electrical charges, they can easily be separated in a strong salt solution for reuse or regeneration. When the salt concentration is reduced, the polymers bind again to their mozzarella-like structure.

‘Our result is truly a joint effort, where different expertise from the team members came together,’ De Vos says. ‘Material expertise from Saskia Lindhoud mixed with the ‘golden hands’ and the perseverance of Ameya Krishna made it possible to develop this subtle process. Now we are ready to further improve the membrane and extend its applications.’

![]()