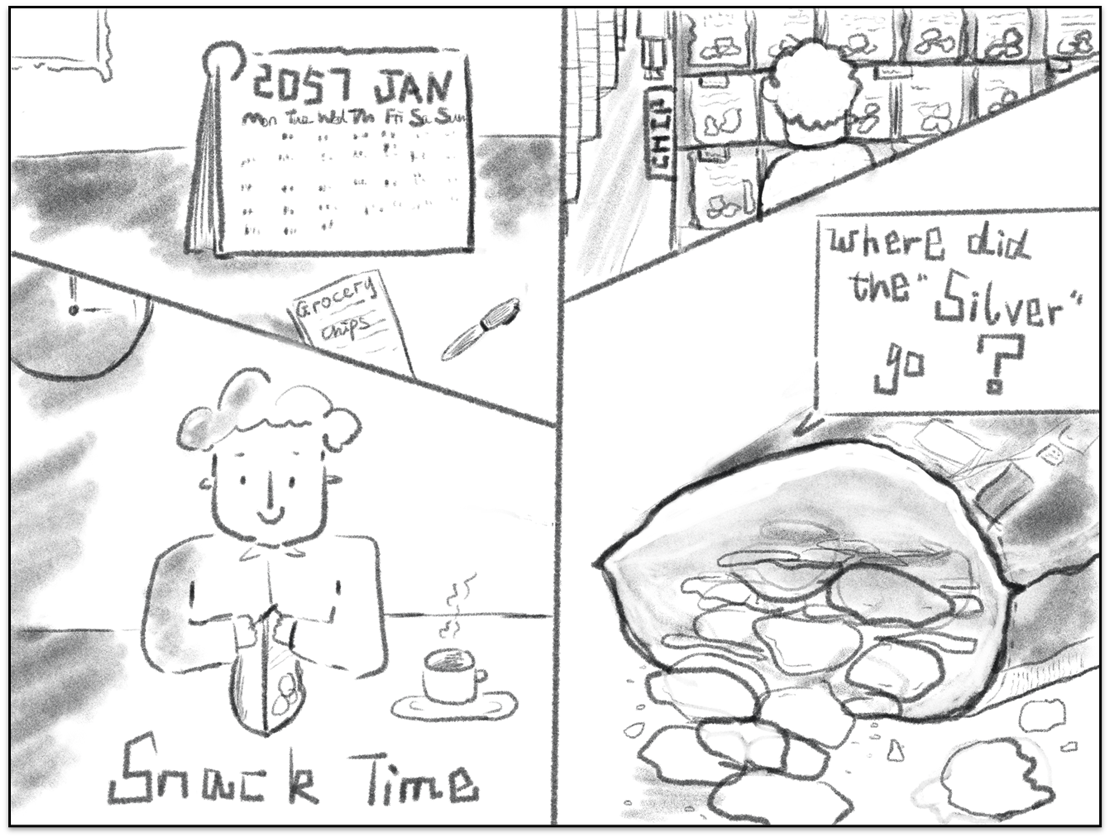

If it is up to UT-PhD student Jiaying Li, we will no longer have a ‘silver’ layer in food packages like crisps bags. In her latest publication, she describes a relatively easy method to create recyclable coatings for food packages. Her research paves the way for food packages that – given the right conditions – can be recycled in water. She recently published her work in the scientific journal ACS Applied Materials & Interfaces.

If you’re a potato crisps lover, you’ve probably noticed that most crisps bags have a ‘silver’ inner layer. While not really silver, but aluminium-based, this layer protects the crisps from oxygen in the air, preserving their crunchiness and preventing it from going bad. However, this layer makes it incredibly hard to recycle the bag. This is why most crisps bags end up incinerated, on landfills or in nature.

Multi-layered problem

The thin layer of packaging is actually multi-layered, existing of different materials – each with their own function – laminated together. These layers are hard to separate, making them difficult to recycle. Li is working on a solution in which the multiple materials are replaced by a single layer that performs more than one functionalities in order to reduce the number of layers. “This is already possible with polymers, but traditional polymers are hard to recycle and only soluble in organic solvents”, explains Li.

Polyelectrolyte-based coatings

Polyelectrolyte-based coatings are the solution, according to Li. These coatings can be used as an oxygen barrier and – by introducing the right conditions – are dissolvable in water. “They are not new. However, similar to lasagne, these coatings have to be built layer by layer. Every layer of this lasagne takes around 30 minutes to make making it difficult to industrialize”, says Li. Li’s method reduces the time needed significantly, by preparing a liquid with both positively- and negatively-charged polyelectrolytes and blocking their interaction. When the drying starts, the liquid starts to form a dense layer that serves as a protective layer.

Comic made by Jiaying Li

For the future

At this moment, this method is proven to work for the synthesized polyelectrolytes. The next goal is to use bio-derived polyelectrolytes. These polyelectrolytes are 100% natural-based, for example, extracted from shrimp shells or trees. All of this, hopefully, leads to a future without ‘silver’ in our crisps bags.

More information

This project is a part of the ARC-CBBC multilateral research programme Coatings. This close collaboration between universities (University of Twente and Wageningen University & Research) and companies (BASF and AkzoNobel) is really aiming at bridging the gap between pure research and what it can give back to society. Jiaying Li is a PhD student in the Membrane Science and Technology cluster (MST; Faculty of S&T). Her supervisor is Prof Dr Wiebe de Vos. The article, titled Single-Step Application of Polyelectrolyte Complex Films as Oxygen Barrier Coatings, is open access and can be read online.

More recent news

Thu 20 Apr 2023Successful and inspiring Twente membranes Day 2023

Thu 20 Apr 2023Successful and inspiring Twente membranes Day 2023 Fri 14 Apr 2023Unique Waterlab opens on UT campus

Fri 14 Apr 2023Unique Waterlab opens on UT campus Tue 31 Jan 2023ERC Consolidator Grant for mosaic membrane development by Wiebe de Vos

Tue 31 Jan 2023ERC Consolidator Grant for mosaic membrane development by Wiebe de Vos Tue 17 May 2022Membrane filtration pilot with new wastewater treatment technology

Tue 17 May 2022Membrane filtration pilot with new wastewater treatment technology Mon 7 Feb 2022ERC Proof of concept grant for Wiebe de Vos

Mon 7 Feb 2022ERC Proof of concept grant for Wiebe de Vos