OBJECTIVE

To improve the reactivity of natural rubber towards silica in order to make it more suited for reinforcement of tire-treads.

CHALLENGE

The current high dispersion silica passenger-tire technology utilizes ‘solution-polymerized’ synthetic elastomers like Solution Styrene-Butadiene Rubber (sSBR) and Solution Butadiene Rubber (BR). At present silica technology is not feasible in combination with “emulsion-polymers”: Natural Rubber (NR); or synthetically produced in latex emulsion polymerization, like e.g. Emulsion Styrene-Butadiene Rubber (E-SBR), the most commonly used alternative for NR in tires. The reasons for the ineffective coupling of the silica to NR are not well understood. It is postulated that non-rubber constituents in NR such as proteins as well as emulsifiers in E-SBR compete with the coupling agents for reaction with the silica, so disturb its reinforcement.

RESULTS

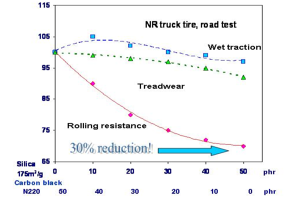

Silica has a strong positive influence on reduced rolling resistance (fuel saving) and lower heat build-up as compared to carbon black in NR compounds. Field tests with NR truck treads have demonstrated that the rolling resistance can be improved by as much as 30% when silica is used to replace carbon black. The treadwear index decreases by no more than 5% and wet traction shows only little changes.

BENEFIT

NR represents >40% of the world rubber consumption, and the market share tends to increase even. The combination of silica technology with NR will produce more environmentally-friendly tires. NR is one of the most ideal examples of sustainable energy generation, where CO2 is taken from the air in vast areas of the world to produce this natural polymer, and the trees after their service life are used for furniture production.

For more information regarding this project, contact S. Sarkawi MSc