We have various equipment components available for research in our wind tunnel laboratory. The most notable systems are listed below.

- Velocity

Hot-wire anemometry

Hot wire anemometry is a technique in which a thin wire is heated electronically. As fluid flows past the wire, heat is convected away, causing a change in the wire's resistance. By measuring this change in resistance, the velocity of the fluid flow can be determined.

Hot-wire anemometry offers several advantages, such as high frequency response and excellent spatial resolution. It can be used to measure both steady and unsteady flow velocities in various applications, including boundary-layer studies, turbulence research and mean flow characterization around objects.

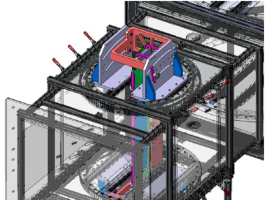

Our research facility is equipped with state-of-the-art hardware and software from Dantec Dynamics. We utilize a range of probes, including one-dimensional, two-dimensional, and boundary-layer probes, along with a three-dimensional traversing mechanism for automated comprehensive measurements.

PIV

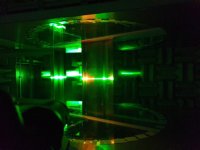

Particle Image Velocimetry (PIV) is a non-intrusive optical measurement technique used to obtain quantitative information about fluid flow fields. In PIV, tracer particles are added to the fluid flow. These particles are illuminated with a laser and a camera captures images of the particle motion at a high rate. By analyzing the displacement of groups of particles between successive image frames, the velocity vectors of the fluid flow can be determined. This is achieved through a cross-correlation technique.

PIV provides high-resolution velocity measurements over a large area, allowing for detailed analysis of flow patterns and vortices. Instantaneous, time-resolved and time-averaged flow fields are captured making this technique suitable for transient and steady-state flows.

PIV provides high-resolution velocity measurements over a large area, allowing for detailed analysis of flow patterns and vortices. Instantaneous, time-resolved and time-averaged flow fields are captured making this technique suitable for transient and steady-state flows.  Our wind tunnel facility is equipped with a low-speed and high-speed laser with a maximum repetition rate of 15 Hz and 10 kHz respectively. A laser guide arm can be used to ensures optimal placement of the laser light. Two types of seeding particle techniques can be used: DEHS and helium-filled soap bubbles for small and large volume measurements respectively. An assortment of low-speed and high-speed camera's can be used to capture images of the tracer particles. PIV data is processed using the DaVision software solution by LaVision. We have the capacity to conduct measurements ranging from 2D to 3D and two velocity components to three velocity components.

Our wind tunnel facility is equipped with a low-speed and high-speed laser with a maximum repetition rate of 15 Hz and 10 kHz respectively. A laser guide arm can be used to ensures optimal placement of the laser light. Two types of seeding particle techniques can be used: DEHS and helium-filled soap bubbles for small and large volume measurements respectively. An assortment of low-speed and high-speed camera's can be used to capture images of the tracer particles. PIV data is processed using the DaVision software solution by LaVision. We have the capacity to conduct measurements ranging from 2D to 3D and two velocity components to three velocity components. PTV

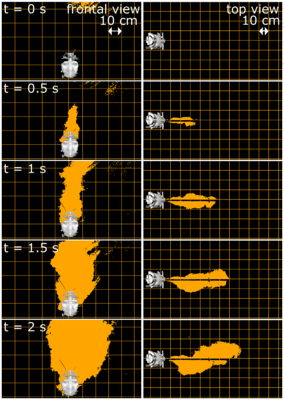

Particle Tracking Velocimetry (PTV) is an optical measurement technique used to analyze fluid flow. Tracer particles are added to the fluid flow and illuminated by a laser, similar to PIV. In PTV, individual particles are tracked, allowing the individual trajectory of particles to be determined. PTV provides detailed flow information, especially in complex and three-dimensional flow. Flow fields can be analyzed with high spatial and temporal resolution.

Particle Tracking Velocimetry (PTV) is an optical measurement technique used to analyze fluid flow. Tracer particles are added to the fluid flow and illuminated by a laser, similar to PIV. In PTV, individual particles are tracked, allowing the individual trajectory of particles to be determined. PTV provides detailed flow information, especially in complex and three-dimensional flow. Flow fields can be analyzed with high spatial and temporal resolution. PIV data is processed using the DaVision software solution by LaVision. We have the capacity to conduct measurements ranging from 2D to 3D and two velocity components to three velocity components.

Other

In addition, we have a variety of other measurement techniques to quantify fluid velocity. These include pressure-based velocity measurements using Pitot-tubes, dynamic head probes and flow direction probes. Furthermore, we have a range of flow visualization methods at our disposal, such as smoke visualization and the use of tufts for visual assessment of flow patterns.

- Pressure

Pressure measurements play a crucial role in the field of aerodynamics and aeroacoustics, providing valuable data for understanding and analyzing fluid flows aerodynamic sources and acoustic phenomena. Various techniques can be used to measure pressure.

Dynamic, Static and total pressure

Pitot-static and static pressure ports enable the measurement of total and static pressure to determine pressure gradients, airflow velocities and pressure coefficients. These measurements can be used to analyze aerodynamic forces, steady flow fields and other flow characteristics. We utilize various types of pressure transducers for different applications.

Barometric pressure

The barometric pressure in our anechoic chamber is continuously monitored and can be recorded during a measurement.

- Acoustics

Analog Microphones

Analog microphones are commonly used in aeroacoustic measurements to analyze aerodynamics sound. Single microphones can be used to obtain basic acoustic characterisation of test objects such as scaling laws, directivity patterns or standard noise metrics such as the equivalent sound pressure level, loudness, A-weighted sound levels, tonality, or peak sound levels. We operate a broad range of analog microphones such as the LinearX M51 and GRAS 40-PH. Microphone signals are recorded using PXI-e-4499 Sound and Vibration modules installed in a NI PXIe-1073 chassis.

Analog microphones are commonly used in aeroacoustic measurements to analyze aerodynamics sound. Single microphones can be used to obtain basic acoustic characterisation of test objects such as scaling laws, directivity patterns or standard noise metrics such as the equivalent sound pressure level, loudness, A-weighted sound levels, tonality, or peak sound levels. We operate a broad range of analog microphones such as the LinearX M51 and GRAS 40-PH. Microphone signals are recorded using PXI-e-4499 Sound and Vibration modules installed in a NI PXIe-1073 chassis. Digital Microphones

Digital microphones, also known as microelectromechanical systems (MEMS) microphones provide numerous avantages in aeroacoustic applications. Their high SNR, wide frequency response, large dynamic range, compact size, direct digital output and stability make them well-sutied for capturing and analyzing sound signals in aeroacoustic studies. Our team has first-hand experience in the design, production, implementation and application of digital microphone systems in various aeroacoustic applications.

Digital microphones, also known as microelectromechanical systems (MEMS) microphones provide numerous avantages in aeroacoustic applications. Their high SNR, wide frequency response, large dynamic range, compact size, direct digital output and stability make them well-sutied for capturing and analyzing sound signals in aeroacoustic studies. Our team has first-hand experience in the design, production, implementation and application of digital microphone systems in various aeroacoustic applications. Remote Microphone Probes

The remote microphone technique is a method used to capture and analyze sound signals at a remote distance from the sound source. This technique is commonly employed in situations where direct placement of a microphone near the sound source is impractical or not feasible due to physical constraints or desired spatial coverage. Efficient utilization of this technique requires careful consideration associated with signal degradation over large distances, environmental noise interference and proper microphone placement. We have first-hand experience with the design, manufacturing, implementation and calibration of this technique.

Microphone Arrays

Microphone arrays are systems comprising multiple microphones arranged in a specific configuration to capture a visual image of a sound source. By combining signals from different microphones, information can be obtained about sound source locations by using beamforming. Beamforming is a technique used to focus the microphone signals towards specific sound sources or directions. With this technique, individual sound sources can be localized and quantified, and unwanted noise can be supressed. Our team has gained extensive experience with microphone arrays and developing beamforming algorithms in-house such as CBF, CLEAN-SC and DAMAS. This allows us to optimize sound measurements in our aeroacoustic wind tunnel, enhancing spatial resolution and noise suppression from low to high frequencies. We utilize custom microphone arrays for sound source localization and directivity measurements as well as commercial platforms such as the CAE Systems Bionic-M microphone array and CAE Systems portable real-time Sound Cam.

- Force

Force balance

A force balance is a fundamental tool used in aerodynamics and aeroacoustics to determine forces acting on testobjects. A force balance typically consists of a sensitive mechanism that accurately measures forces experiences by an object. The mechanism can include strain gauges, load cells or other transducers. We utilize force balances manufactured by specialized companies and have the capability to incorporate straing gauges, load cells and torque sensors in simpler configurations.

A force balance is a fundamental tool used in aerodynamics and aeroacoustics to determine forces acting on testobjects. A force balance typically consists of a sensitive mechanism that accurately measures forces experiences by an object. The mechanism can include strain gauges, load cells or other transducers. We utilize force balances manufactured by specialized companies and have the capability to incorporate straing gauges, load cells and torque sensors in simpler configurations. Indirect measurements

Aerodynamic forces can also be estimated using indirect measurement techniques. For this purpose we can utilize various techniques, such as wake rakes, hot-wire anemometry, PIV, static pressure on the wind tunnel walls or pressure sensitive paint.

Aerodynamic forces can also be estimated using indirect measurement techniques. For this purpose we can utilize various techniques, such as wake rakes, hot-wire anemometry, PIV, static pressure on the wind tunnel walls or pressure sensitive paint. - Displacement and Strain

Digital Image Correlation (DIC)

- Inflow Conditions

Turbulence Grids

- Models

- Other

Schlieren