Virtual Prototyping of Particulate Processes

This project has been granted to Thomas Weinhart by the NWO-VIDI Scheme.

Summary

Particulate materials are the most manipulated substance on the planet, after water. They are of paramount importance to the chemical-pharmaceutical, agri-food, energy, high-tech manufacturing, mining, and construction industries.

However, their unique behaviour cannot be captured comprehensively in macroscopic (continuum) models, while microscopic (discrete) models are too inefficient to resolve the enormous number of particles. This has so far prevented the development of efficient computational models for particulates, which already exist for fluids and solids. Hence, while cars and airplanes are nowadays designed on the computer, particulate industries still rely on time-consuming and expensive experimentation.

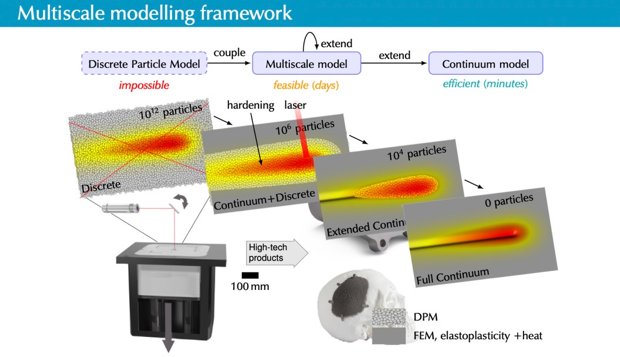

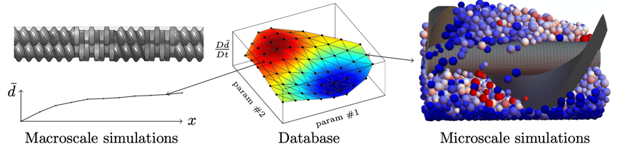

To facilitate virtual prototyping for particulate systems, this project will use a novel multiscale approach: The method microscopically resolves regions where current macroscopic models fail (see figures). From these multiscale simulations, we will extract efficient, application-specific macro-models that are utilised to design innovative processes. Two timely applications will be developed in collaboration with industry: additive manufacturing, the future of many high-tech industries; and continuous granulation, an aspiration of the pharma industry. For validation and calibration, rapid prototyping will be used to create miniature setups, which can be simulated fully on the micro-scale.

The central pillar of this project is coarse graining: an innovative new coupling technique, developed by the PI, that is used by universities and industry around the world. Via coarse-graining, the team will integrate two highly regarded open-source softwares, MercuryDPM and oomph-lib. We will be the first to apply goal-oriented refinement to particulate systems, guaranteeing efficiency and robustness of the integrated software.

All advanced algorithms created by this project will be released open source, meaning immediate dissemination to academia and industry. This will enable a significant speed-up in the design and optimisation of numerous particulate processes.

Figure 1: Powder Bed Printing modelled in a multiscale fashion, using a volume-coupling approach.

Figure 2: Twin-screw granulation modelled in a multiscale fashion, using a heterogeneous coupling approach with a population balance model.

People involved