PROJECT AIM

Granular segregation is a major problem to numerous industries, which often rely on empirical rules of thumb to predict non-segregating operating conditions. The aim of this project is to understand the fundamental cause(s) of segregation, particularly in rotating drums, which are investigated using particle simulation tools (MercuryDPM) and particle analysis tools (MercuryCG)...

PROJECT DISCRIPTION

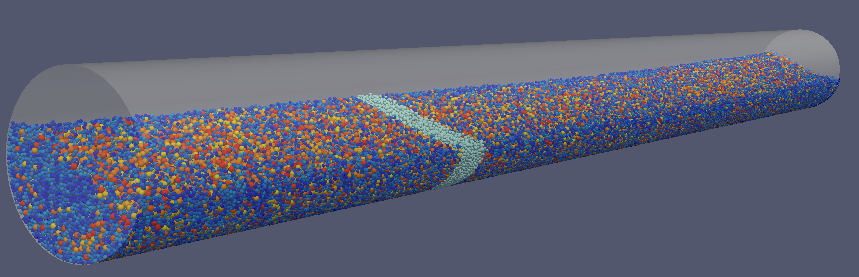

To investigate segregation, we performed particle simulations of chute flows of similar-sized particles containing one ‘intruder’ particle of deviant size. The intruder particle is kept at a fixed height normal to the planar chute, to determine the average segregation force acting on the particle. Analysis of the macroscopic field data (density, flow/strain, stress tensor, etc) is currently in progress, using the open source coarse graining tool MercuryCG. Furthermore, MercuryDPM has been adapted to parallel computing. This enables investigation of the extremely slow axial segregation process of bidispere granular beds in rotating long drums.

Figure 1. Snapshot of a bed of large (yellow/red) and small (blue) granules in a rotating drum. The simulation runs in parallel, with the white band indicating the workload of one core.

2019 Dissertation

M.P. van Schrojenstein Lantman, A study on fundamental segregation mechanisms in dense granular flows, University of Twente, 25 April 2019.

PEOPLE INVOLVED

Dr. M.P. van Schrojenstein Lantman (Marnix)