summary

The aim of this project is to quantitatively predict bulk processes such as agglomeration through compression and/or heating. This will require the development and calibration of new multi-scale particle models for fine powders and their application to processes in additive manufacturing, pharmaceutics, process and mechanical engineering, geotechnics, etc; selective laser sintering (SLS) and tabletting are chosen as the prototype processes to which the new techniques are applied first. The resulting numerical and analytical methods will be capable of quantitative predictions for a wide range of situations, helping to understand the fundamentals of agglomeration, but also allowing to optimise processes in the future. An especially challenging and novel aspect is the process dynamics (kinetics and rate-dependence) as well as the coupling between the individual scales.

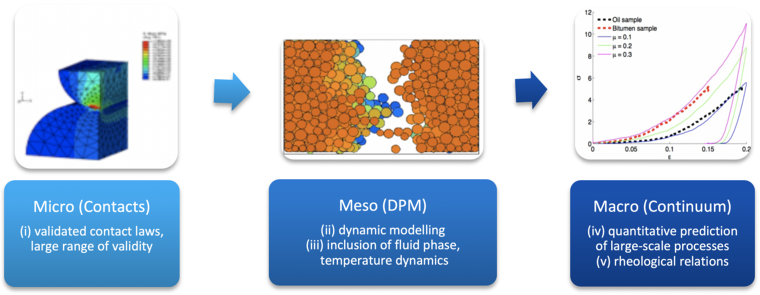

Fig. Schematic overview of the meso-scale modelling philosophy: The meso-scale model is based on (microscopic) contact information to predict (macroscopic) processes such as tension/compression experiments, tabletting and SLS. (Left) High-resolution FEM contact model. (Centre) Calibrated meso-scale DPM. (Right) Stress-strain in uniaxial compression.

The technical aim of the project is a mesoscale model that allows (i) the inclusion of results from microscopic modelling, (ii) calibrated dynamic modelling on the mesoscale, i.e., validated by experiments, (iii) the inclusion of moisture and the interaction with the surrounding fluid in tabletting processes and the temperature dynamics in SLS into the mesoscale model, and, ultimately, (iii) the quantitative prediction of macroscopic processes and model parameters by developing new constitutive rheological relations.