The Administrative Agreement, which was made in July 2022 between the Ministry of Education, Culture and Science, UNL and the Association of Universities of Applied Sciences, announced Starter and Incentive Grants as a funding instrument to reduce the workload at universities and strengthen independent research. UT has completed internal decision-making on this instrument and awarded the first batch of Starter Grants to eligible UDs (based on the criteria from the Administrative Agreement). In addition, UT made 24 Incentive Grants with a maximum size of 240k€ available once only for UDs, UHDs and tenured professors. For ET the Faculty board made five Incentive Grants available for the research themes.

Incentive Grants ET

Asset & Maintenance Engineering

The Incentive Grant rewarded to the ET faculty research theme Asset & Maintenance Engineering is dedicated to the Lifetime Performance Laboratory that is currently being realised. The objective of the lab is to test materials and constructions at sub-component scale under extreme conditions. This allows to accelerate wear and degradation of real scaled structures, greatly improving predictive models and supporting newly developed monitoring concepts and systems. This will provide fundamental insights in the mechanisms determining the actual wear and degradation of materials and systems under realistic circumstances and detect onsets of damage at an early stage and will significantly improve the predictability of maintenance needs and interventions.

The budget of the grant will partly be used to invest in the necessary hardware, such as a modular (hydraulic) loading frame, to introduce multiaxial loadings to a broad variety of test objects. A showcase experiment, based on a composite structure with advanced and embedded sensor technology, will be built up and subjected to cyclic loading conditions. Secondly, a bearing test machine and a rain erosion set-up (re-)installed and prepared for showcase experiments. The results will be dissemination via various publication routes, clearly demonstrating the capabilities of the laboratory as well as the academic value.

Resilience Engineering

Game-based approaches for improving resilience in a changing world: the case of drought resilience in Eastern Netherlands

Resilience too often remains a theoretical concept that is difficult to grasp, assess and implement by practitioners. To make resilience a more actionable concept, we propose a multidisciplinary project that aims to develop game-based approaches to building resilience. The PhD project will combine insights, methods and tools for system analysis, eliciting stakeholder perspectives, designing serious games and developing transition pathways towards improving resilience. The empirical focus will be on drought resilience in the Eastern Netherlands through a valuing water perspective. The project will i) develop a conceptual framework and indicators for valuing limited resources, ii) elicit stakeholders perspectives on multiple values through serious gaming and iii) explore transition pathways based on scenario analysis of probable future climate characteristics and socio-economic developments. Cross-departmental collaboration in the ET Faculty will play an important role in identifying and transferring key principles and mechanism across domains (e.g. transport, energy, humanitarian engineering), and developing an understanding of interacting impacts and societal transitions beyond the water sector. To achieve such collaboration, the PhD candidate and its supervisors initiate regular meetings with members of the Scientific Steering Committee (see above), initiate cross-departmental MSc thesis projects, and collaborative sessions at events such as the Risk and Resilience Festival.

Expected impacts include:

- Proof of concept for engaged, societally relevant research on resilience engineering.

- An improved scientific understanding of the role of game-based methods and valuing water concepts in identifying solutions for improved resilience to droughts and their applicability to other societal challenges.

- Strong impetus to the desired collaboration between UT and key regional stakeholders on resilience and drought resilience in particular.

- Use of game-based approaches and valuing water concepts in resilience-oriented education courses.

Personalised Health Technology

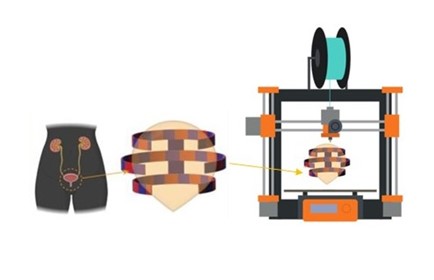

PRIMA: 4D PRInting of multifunctional smart Medical Actuators

Biomedical devices are routinely used within the human body, in the form of implants and as diagnostic or therapeutic tools. Typically, these devices are designed for passive implantation and cannot be actively controlled once inside the body. This leads to medical complications in case of unforeseen circumstances, necessitating additional surgical procedures and causing distress for the patient. Some medical devices require battery sources and other components, making them bulky and prone to maintenance issues. The limited design and manufacturing options also mean that clinicians must choose from a small range of options, and personalizing devices to specific patient needs is prohibitively expensive.

To overcome these limitations, the PRIMA project proposes the development of a manufacturing approach for novel medical devices that can be effectively controlled from outside the patient's body using different stimuli. The utilization of 3D printing technology allows for the customization of medical devices tailored to case-specific and patient-specific requirements. This project will involve close collaboration among the Advanced Manufacturing, Sustainable Products & Energy Systems (AMSPES), Surgical Robotics (SR), and Thermal Engineering (TE) groups within the Faculty of Engineering (ET) at the University of Twente.

Sustainable Production, Energy, and Resources (SuPER)

The Sustainable Production, Energy, and Resources (SuPER) theme has launched two new research HUBs: the HUB for Functional Materials for Sustainable Cooling and the HUB for a Sustainable Net-zero Transition of Industry. The former addresses the imperative for clean and efficient cooling solutions, aiming to explore synergies between advanced manufacturing, computational modeling, and sustainable cooling practices. This HUB intends to delve into fundamental science and engineering of materials, focusing on tailoring and controlling functions within thermodynamics, kinetics, and heat and mass transport. The latter HUB focuses on assisting the industry sector in implementing innovative solutions to reduce energy demand, environmental footprints, and costs across industrial processes, manufacturing facilities, and associated logistic equipment. This is achieved through the development of methodologies and tools that comprehensively map energy use and flows, and quantify energy-related environmental impacts and costs.The strategic objective of the two research HBUs is to foster connections among researchers across various departments who are tackling similar societal challenges, facilitating the exchange and cultivation of ideas for prospective collaborations. The HUBs extend an invitation to all UT researchers engaged in related fields to join regular meetings and discussions, promoting active participation.

Intelligent manufacturing systems

Intelligent manufacturing systems is an interdisciplinary ET theme which addresses different future oriented process technologies (e.g. additive manufacturing), automation solutions, machine design, product engineering and manufacturing systems/factories. Digitalization is a key aspect, e.g. a variety of computational models in combination with tailored data acquisition is involved. Through the incentive grant two joint demonstrators/platforms will be established that involve all related departments and can be used for further research, education and demonstration of the IMS theme: one demonstrator will cover different technological and modelling aspects around multi-material (powder-based) additive manufacturing (AM) which will be brought together towards deeper system understanding and improved designs. The second demonstrator focuses on a machine demonstrator around sheet metal/foil forming e.g. in the area of battery or fuel cell production. It aims at establishing data based insights while connecting sensor data to different models on process and machine level towards process control or condition monitoring.