The SMART group is a dynamic and innovative team committed to advancing the manufacturing of Smart Materials and Structures. Our primary focus is on additive manufacturing technologies to pioneer the design and fabrication of multifunctional materials and structures.

At SMART, we understand that the future of manufacturing is not just about producing goods, but also about creating intelligent, adaptable, and responsive materials and structures that can revolutionize industries and future products. Therefore, we aim to push the boundaries of what's possible, enabling breakthroughs in fields ranging from aerospace and automotive to healthcare and beyond. Our focus on innovation, efficiency, and sustainability drives us to explore new avenues and push the envelope of technological progress, thus making a meaningful impact and shaping the future of manufacturing worldwide.

Additionally, we've organized a series of scientific webinars focused on the exploration of Advanced Manufacturing of Smart Materials and Structures (AM-SMART). For further details, we invite you to visit the website and explore the LinkedIn page.

If you require additional information or are interested in collaboration, please contact the topic leader:

dr.ir. M. Mehrpouya (Mehrshad)

Assistant Professor

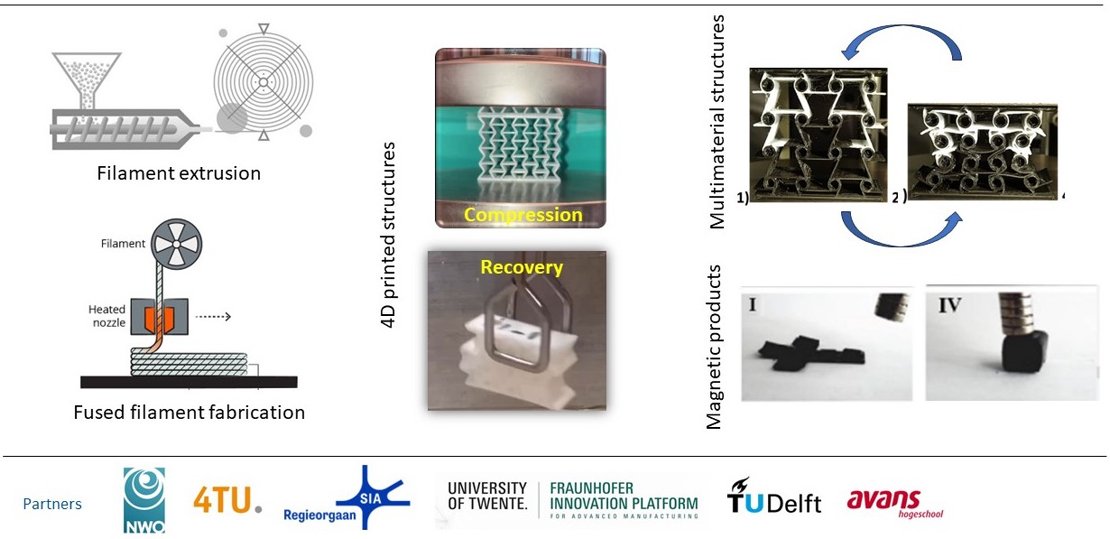

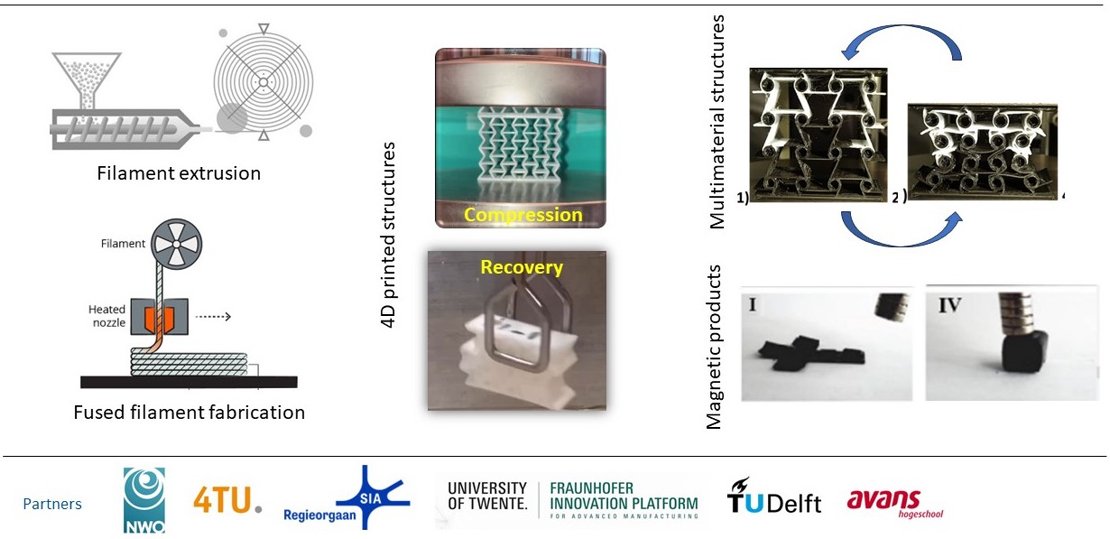

SMART ARCHITECTED STRUCTURES

Additive manufacturing of functional materials has garnered significant attention in the past decade. This technology facilitates the fabrication of complex-shaped products, including architected structures. Our focus lies in the development of smart and multifunctional structures capable of reverting to their original shape after deformation, driven by external stimuli, a cutting-edge technology known as 4D printing. Additionally, we possess the capability to create novel materials and composites tailored for 3D printing, such as printing filaments.

A. Ghalayaniesfahani (Ava)

PhD Candidate

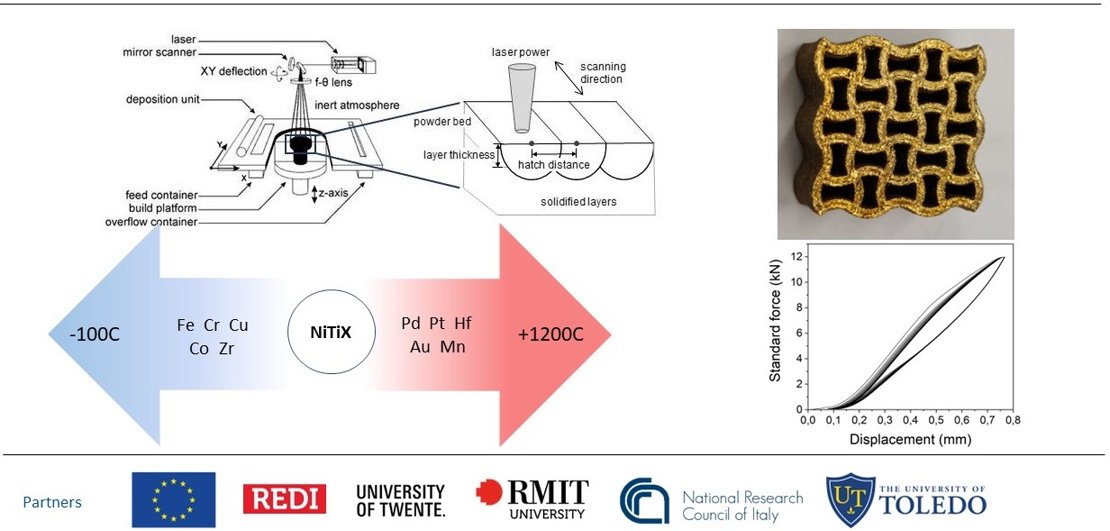

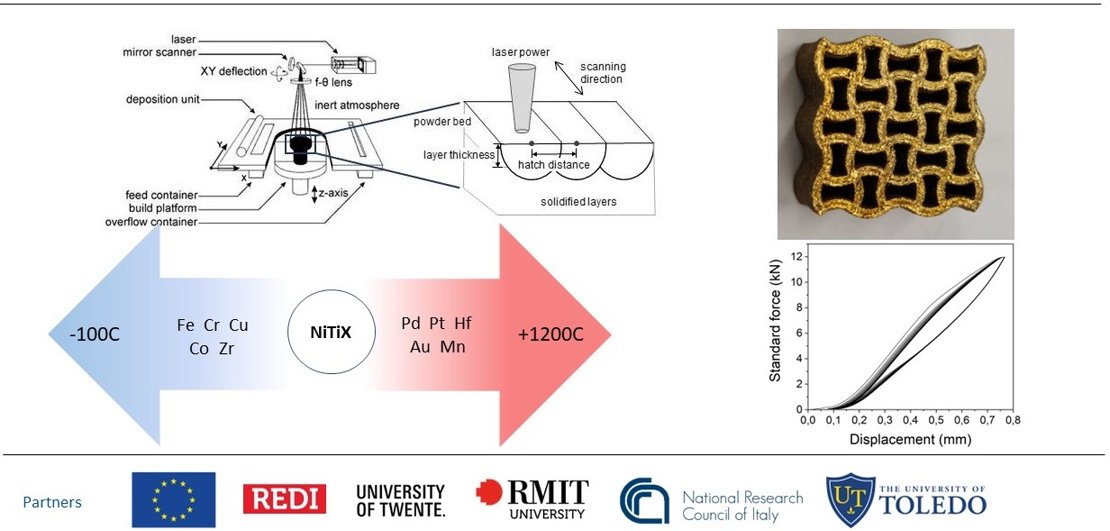

ADDITIVE MANUFACTURING OF SHAPE MEMORY ALLOYS

Additive manufacturing of shape memory materials offers a distinctive opportunity for the design and creation of intelligent structures with superelastic and shape memory characteristics. Our research focuses on the additive manufacturing of shape memory alloys (SMAs) utilizing laser powder bed fusion (LPBF) and laser metal deposition (LMD) techniques. In doing so, we place particular emphasis on the evaluation of process parameters and their influence on the functional performance of the 3D printed components. Furthermore, we explore the effects of introducing additional elements, such as NiTiX, on the thermomechanical and functional properties of the novel alloy.

E.T.A. Salaheldin Abdelhady (Eslam)

Marie Skłodowska-Curie fellow

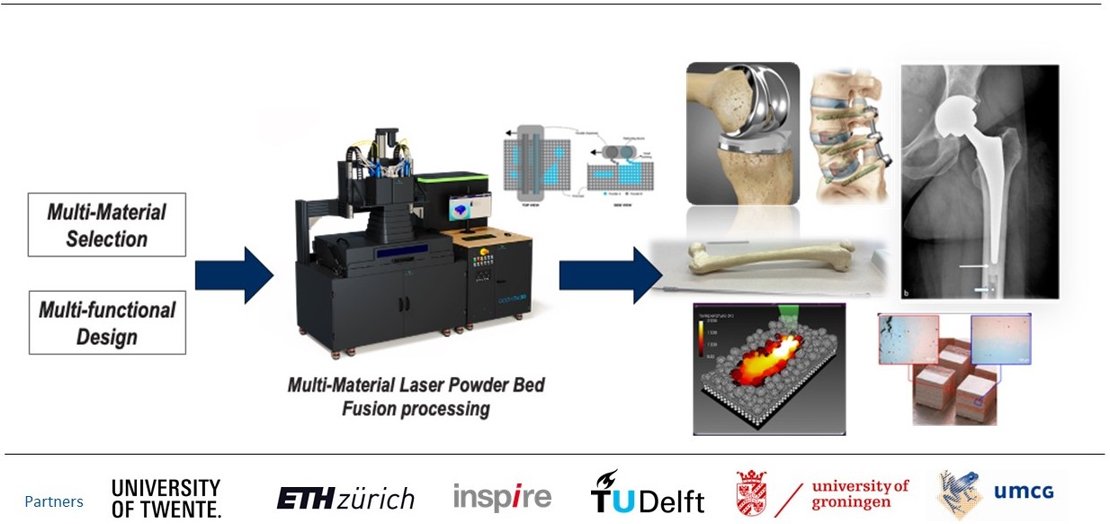

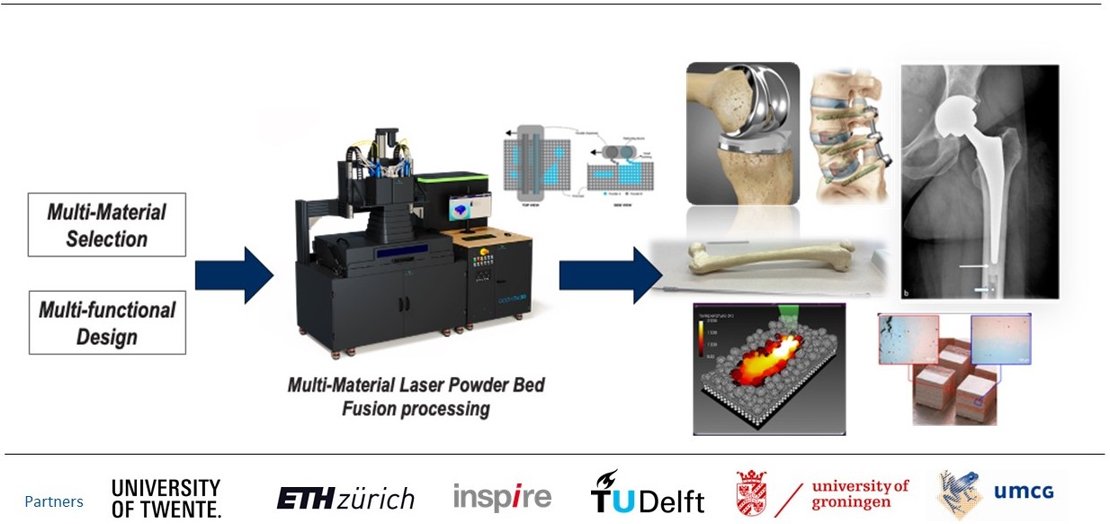

ADDITIVE MANUFACTURING OF MULTIMATERIAL AND MULTIFUNCTIONAL STRUCTURES

Multimaterial 3D printing offers unique opportunities for designing and developing products with functionalities that cannot be achieved otherwise. There are several potential applications for such structures. The medical field stands out due to the adaptability of this technology, which is employed in various medical devices. Typically, existing 3D-printed products consist of only one material. However, the concept of a multi-material component can provide advantages by combining different properties in a single part. In this project, a multi-material component with tunable functional performance is the aim to achieve. For that, it is necessary to select proper alloys, and printing process parameters, and study the bonding quality and their interface depth from the materials perspective, in order to design a real case for AM at the final stage is foreseen to be achieved through this project.

H. Moutablaleh (Hadi)

PhD Candidate