Tire noise is becoming the main source of car noise due to the ever decrease is car engine noise. Hence, tire manufacturers put nowadays more emphasis in reducing tire noise radiation. To conform to the tightening noise standards set by European legislation, the tire manufacturer wants to predict the effect of material choice and tire tread on the amount of noise radiation early in the design phase. Hence, the infamous magical triangle of tire technology (rolling resistance, wear, grip) should be extended with an additional dimension (noise) which makes the quest to find the optimal tire even more complex.

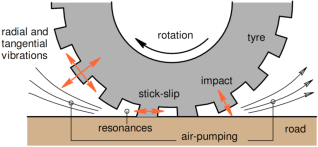

Mechanisms that effect tire noise generation

The initial source location of tire noise is the contact area between tire and road. As a result of this contact dynamic loading of the tire takes place, i.e. the tire starts to vibrate hereby radiating sound. Besides, in the contact area, air pumping occurs (between tire tread and road surface) which adds to the tire noise.

A numerical model for the prediction of tire noise should be able to:

- Describe the dynamic behavior of the tire;

- Compute the amount of tire noise due to tire vibrations;

- Compute the amount of tire noise due to air pumping;

- Pinpoint the dynamic loading in the contact area.

However, the numerical models which can calculate the noise radiation till 2000 Hertz, are computationally very expensive. Currently, it is yet not feasible to use these models in a design stage to their full extent.

The main factor influencing the computation time is the required level of accuracy to predict the noise radiation, which is directly linked to the way the dynamic behavior in the contact area is modeled. Within the group SDA research is carried out on the development and application of a fast and effective advanced contact algorithm. This contact method will be coupled to the other three mentioned models, leading to a numerical tire noise model which can be used in the design stage.

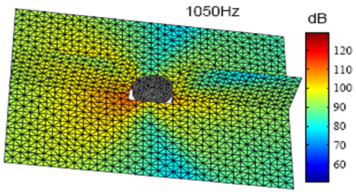

Noise level in decibel (dB) at 1050 Hz (tire without profile, on rigid surface)