Development of stable process flow for manufacturing of Si nano-focussing lenses

Contact: Dr. I.A. Makhotkin, i.makhotkin@utwente.nl

Introduction

The clean-room microfabrication process is the family of techniques aimed to produce micro- and nano-devices for various industries, including semiconductor, photonics and medical applications

We are focusing now on the development of lenses for micro-focus synchrotron beamlines. Synchrotrons are large scale scientific facilities that provide access to scientists and industries to state-of-the-art X-ray characterization techniques. Modern synchrotron radiation sources such as MAX IV, ESRF and the developing project of PETRA IV are based on diffraction-limited storage rings capable of generating ultra-high brilliance X-ray beams. In addition, because of the tiny size of the effective X-ray source, such beams can potentially be focused to nm-size beams using special X-ray optics.

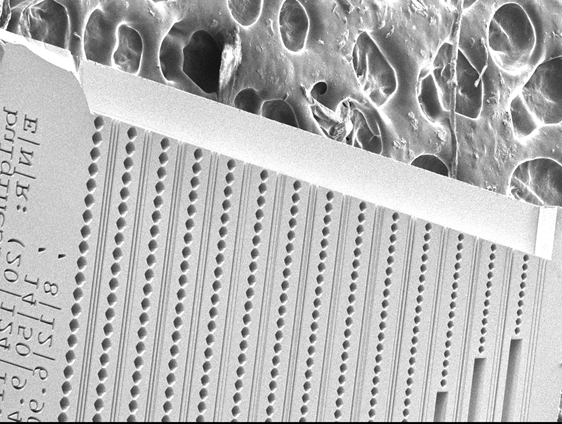

Si nano-focusing lenses (NFLs) are currently one of the most used concepts of transmission X-ray lenses capable of focusing X-ray to sub 100 nm beam sizes. The NFLs are etched into Si wafers. A typical focusing lens consists of an array of identically shaped lenses; see figure below. The quality of the focused spot is directly dependent on the accuracy with which the designed array of lenses can be transferred to Si wafer. In addition, the lenses must have perpendicular sidewalls with minimal roughness over the total depth of ~50 um and more than 100 nm accuracy in the reproduction of the designed pattern into the Si wafer.

A test-recipe was currently developed to fabricate Si NFLs that can achieve the requirement as mentioned above. The problem at hand is that using a current recipe, Si NFLs cannot be reliably manufactured even if all steps of a good recipe are accurately followed. Obviously, specific parameters of setups or processes are not adequately monitored and, consequently, controlled.

Assignment

The project's goal is to develop an improved NFL manufacturing process that will guarantee a reliable NFLs yield. The first step is to allocate the most critical steps in NFL’s manufacturing that are responsible for instability of recopies. The second step is to develop the modified recipe with better stability and a broader process window. Finally, the new recipe need to be tested for the stability of the recipe for various lens designs.

This project is a part of a long-term research collaboration between the University of Twente and DESY photon science(Hamburg). The candidate will receive ample micro-manufacturing experience in the state-of-the-art MESA+ clean room. Finally, the student will experience the reporting of results and development to colleagues in XUV Optics group and our research partners from DESY.