Grease is the most widely used lubricant in the world for rolling bearings. It guarantees smooth and sustained operation of bearings in many industrial applications including electric vehicles, wind turbines and trains. Grease is a soft material that consists of a network of self-aggregated fibres or platelets of a ‘thickener’ (often salts of fatty acids) that retains lubricating oil like a sponge. Its function is to store and gradually release oil towards the contact zone where it reduces friction and wear by preventing direct contact between bearing balls and their ‘rolling track’. This gradual release is ideally lasts throughout the entire lifetime of the bearing, which can be decades. The goal of this project is to qualitatively demonstrate a) that randomly deposited fibers of thickener play an essential role in this process (in current technology) and b) that dedicated coatings of polymer brushes can substantially improve control over the oil release process.

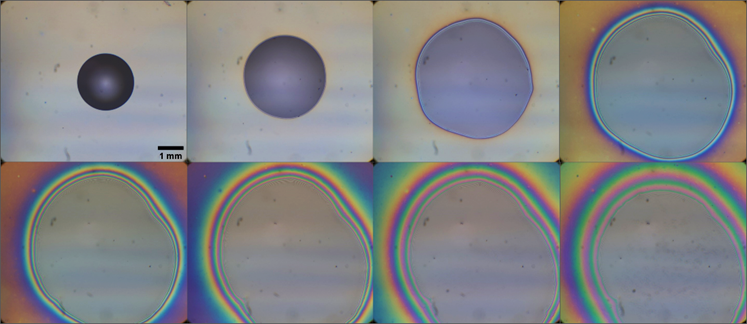

Time series (0 to 48h) of spreading drop surrounded by interference fringes due to precursor film swelling in functional surface coating. (see Ö. Kap et al. J Chem. Phys. 158, 174903 (2023)).

Research Objective

Your specific task will be to test the spreading behavior of oil from a grease droplet to model bearing surfaces that are either untreated or treated with fibers or polymer brush coatings. You will optically monitor the spreading process of the oil and demonstrate its enhancement by the coatings that absorb the oil by capillarity-driven absorption and by swelling, respectively. The primary goal is to explore by how much the coating improve the oil release and to establish the microscopical physical effects that control the enhancement.

Learning Objectives

· Perform optical measurements (video microscopy and/or confocal fluorescence microscopy) to monitor oil release and the spreading process

· Learn about optical image processing and data analysis

· learn about capillary and wetting phenomena along with micro/nanofluidic fluid motion

Contact Information

Daily Supervision: Vincent Siekmann

Supervision: Prof. Dr. Frieder Mugele