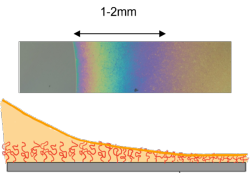

The joints in our bodies are lubricated by swollen polymer molecules that are chemically attached (‘grafted’) to the surfaces of the cartilage of our joints. A very high osmotic pressure stabilizes the aqueous fluids within this polymer layer and thereby guarantees life-long lubrication with a very low friction coefficient. Similar lubrication concepts have recently been adopted to achieve low friction in technological applications. In the present project, we want to explore the use of swollen ‘polymer brush’ layers as low friction substrates for electrowetting (EW) driven microfluidic applications. If successful, such layers could provide a new class of self-healing substrate that might revolutionize electrowetting. In contrast to biological joints, we will use hydrophobic polymers that are directly grown onto silicon wafers and subsequently infused by a controlled amount of oil in controlled environment. (Figure: interferometric image (top) and a schematic (bottom) of the edge of a droplet merging into a partly swollen polymer brush layer (right hand side).)

The joints in our bodies are lubricated by swollen polymer molecules that are chemically attached (‘grafted’) to the surfaces of the cartilage of our joints. A very high osmotic pressure stabilizes the aqueous fluids within this polymer layer and thereby guarantees life-long lubrication with a very low friction coefficient. Similar lubrication concepts have recently been adopted to achieve low friction in technological applications. In the present project, we want to explore the use of swollen ‘polymer brush’ layers as low friction substrates for electrowetting (EW) driven microfluidic applications. If successful, such layers could provide a new class of self-healing substrate that might revolutionize electrowetting. In contrast to biological joints, we will use hydrophobic polymers that are directly grown onto silicon wafers and subsequently infused by a controlled amount of oil in controlled environment. (Figure: interferometric image (top) and a schematic (bottom) of the edge of a droplet merging into a partly swollen polymer brush layer (right hand side).)

Research objective

Your research objective will be to quantify the (static and dynamic) electrowetting response of aqueous drops on solid substrates with a polymer brush coating. You will soak the polymer brush coating with variable amounts of oil. The first goal will be to measure the equilibrium contact angle as a function of the applied voltage for variable degrees of oil saturation and to extract to what extent the shape of the wetting ridge at the edge of the drop varies with voltage. Having established the static behavior you will start to use a high speed camera to measure the dynamic response of the drop to variable electrical waveforms (e.g. step voltage; AC voltage of variable frequency). From these measurements, you will extract the static contact angle hysteresis as well as the dynamic contact line friction coefficient. Depending on your expertise and/or interest, you can either do the required image analysis by hand or by image analysis software (Python/Matlab).

Learning objective

Apart from the standard learning objectives for a bachelor’s project (research planning, academic writing, data presenting, how to work in a lab environment, etc.), you will:

- Obtain knowledge on electrowetting and polymer brush coatings;

- Learn how to carry out electrowetting experiments;

- Learn how to use a high-speed camera;

- Depending on your interests, may analyze images using image processing software or explore the shape of wetting ridges using confocal fluorescence microscopy.

Contact information

Literature

[1] Mugele, Heikenfeld: Electrowetting; Wiley 2019.

[2] A. Keiser et al.: Universality of friction laws on liquid-infused materials; Phys. Rev. Fluids 5, 014005