PhD student : Frank Vroegindeweij

Daily supervisor : Guus Rijnders

Objective of this project is to investigate and fabricate miniature gas sensors, based on thin films made by pulsed laser deposition. By combining thin film technology with smart sensor designs, we are aiming for low-cost, miniature sensors which can compete with costly, commercially available bulk sensors.

Gas sensors

Many gas sensors are available on the market nowadays, serving in very diverse fields of applications: biological, biomedical, chemical, environmental, industrial and research all are areas in which monitoring of the unknown gas environment is necessary. In our search for better performing and cheaper sensors, a lot of effort has been put into strategies to achieve these goals. Improvement of existing devices can be obtained in aspects of working principle, choice of materials and dimensions – which are therefore the subjects of consideration in this project.

The working principles which are under consideration, are for example amperometric, potentiometric, mixed potential and resistive sensors. All have their pros and cons, which can be in aspects like gas pressure detection range, operating temperature, complexity, etc. From these considerations, and from earlier experiences we have decided to investigate miniature potentiometric sensors based on thin films.

Our potentiometric devices

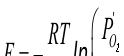

The basis of our potentiometric devices is an oxygen ion conducting electrolyte, Yttria Stabilized Zirconia (YSZ), which is sandwiched between two electrodes. The sensor works according to the Nernstian principle, which states that the open circuit potential can be linked to the oxygen pressures on both sides of the YSZ, according to:

(1)

where E = the open circuit potential, R = the gas constant, T = the temperature, F = Faraday’s constant, and PO2’, PO2” are the oxygen pressures on both sides of the YSZ, respectively. This means that, if the oxygen pressure on one side of the electrolyte can be fixed, the unknown oxygen pressure can be directly calculated.

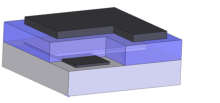

Figure 1: 3D illustration (a) and picture (b) of a O2-sensor based on 8YSZ thin film. The device measures 5 x 5 x 1 mm3.

A binary metal/metal-oxide, which has a fixed oxygen pressure at a certain temperature, is used as internal reference electrode on one side of the electrolyte - and is a key feature of our design. Examples are a Ni/NiO, Ir/IrO2 or Pd/PdO couples.

Another key element in our design is the use of thin films. Application of thin films offers us various advantages: a thin film of YSZ shows an increase in ionic conductivity compared to the bulk, which enables a decrease of the operating temperature (which is favorable in many applications); also, by nano-structuring our sensing electrode, the number of triple-phase-boundaries can be drastically increased which greatly enhances the sensors response time.

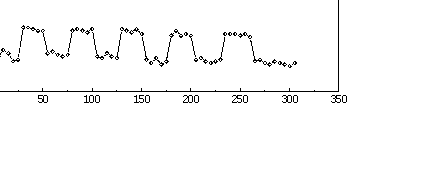

Figure 2: Sensor response to a change in the oxygen content; response time is in the order of seconds.

In practice

In practice this means we are

−making and characterizing electrode materials – trying to link microstructure to sensor performance

−making and characterizing YSZ thin films

−making and testing reference electrode materials

−making and testing O2 – and NOX-sensors

−thinking about how to improve these components to increase the sensors performance in sensitivity, stability and reliability

This project comprises a large dose of materials science and is therefore applied in nature.