[RPLAB]

Formiga P101

Technique | Selective Laser Sintering (SLS) |

Material | Nylone (PA2200) |

Application | Complex shapes and full functional prototypes |

Building Platform | 190*240*300 mm |

Layer Thickness | 60 - 150 Microns |

Laser spot | <500 Microns |

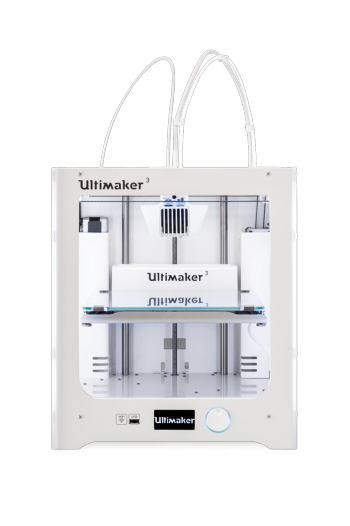

Ultimaker

Technique | Fused Deposition Modeling (FDM) |

Material | |

Application | fast prototypes, multipel colors |

Building Platform | 200*200*200 mm |

Layer Thickness | 60 - 200 Microns |

Printer types |

|

Extruders | Dual extruder - AA: 400 microns - BB: 400 microns |

Uprint-plus

Technique | Fused Deposition Modeling (FDM) |

Material | |

Application | ABS models, |

Building Platform | 200*200*150 |

Layer Thickness | 254 - 330 Microns |

Extruders | Dual extruder - 350 Microns |

______________________________________________________

[RAM Lab]

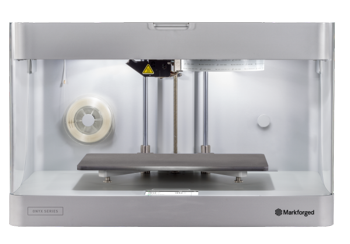

Mark Two

Technique | Continuous Fiber Reinforcement (CFR) |

Material | |

Application | Carbon Fiber reinforced models |

Building Platform | 320*132*154 |

Layer Thickness | 100 - 200 Microns |

ULTIMAKER 5S

Technique | Fused Deposition Modeling (FDM) |

Material | |

Application | fast prototypes, multipel colors |

Building Platform | 330*240*300 mm |

Layer Thickness | 20 - 600 Microns |

Extruders | Dual extruder - AA: 400 microns - BB: 400 microns |

______________________________________________________