Computational MICROMECHANICS

My name is Fengxian Liu. I am an assistant professor of computational micromechanics at the University of Twente. My research focus on computational analysis of materials and structures, with particular focus on multi-scale materials and multi-physics problems. This has broad engineering applications ranging from the power generating industry to Micro-Electro-Mechanical Systems (MEMS).

In 2022, I joined the University of Twente as an assistant professor in the chair of Computational Design of Structural Materials. My Sector Plan research focus on Next Generation Structural Materials. Here, I have further advanced my expertise in metallic materials to explore new material systems, such as oxides and recycled fiber-reinforced polymer composites.

My research aims to advance the understanding of the microstructure-property-performance relationship of materials, exploring the degree to which microstructures are tunable to support the development of advanced materials. This has significant societal impacts, from improving the reliability and efficiency of power generation systems to advancing the performance of everyday consumer electronics. By developing next-generation materials, my work contributes to technological innovations that enhance quality of life and drive economic growth.

Background

I earned my Ph.D. in Mechanical Engineering from Tsinghua University (China) in 2018, focusing on dislocation plasticity for high-temperature applications. After that, I joined the Oxford Micromechanics Group and Solid Mechanics and Materials Engineering Group at the University of Oxford (UK) as a postdoc, expanding my research to the mechanical behaviour of in-core nuclear components in the presence of irradiation damage.

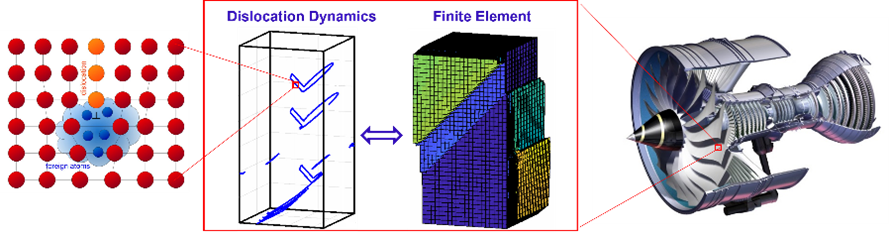

I worked on developing innovative computational methods tailored for metals operating in diverse harsh environments, including radiation damage, high temperatures, high strain rates, hydrogen corrosion, etc., to reveal the underlying dislocation mechanisms that govern mechanical behaviours.

In the years to come

Developing advanced materials relies on a profound understanding of microstructural defect physics. Like human DNA shapes traits, microstructural defects govern material properties. These defects interact intricately, serving as the gateway to potential material failures. My ambition is to decode these complexities through computational tools, extending scientific insights into defect engineering, much like 'gene editing', to precisely craft properties for next-generation materials.

Education

Aligned with my dedication to advancing knowledge, I contribute to education by teaching courses to students at UT. Within the Mechanical Engineering program, I teach the bachelor course “Materials Science” and co-teach the master course “Solids and Surfaces”. Additionally, I supervise bachelor students in their graduate projects.

Collaborations

National and international collaborations are pivotal to my research. As a numerical modeler, I work with experimentalists, materials scientists, and engineers to understand e the mechanical behaviors of diverse materials. Currently, ongoing research involves close collaboration with the Department of Design Production & Management and the Department of Thermal and Fluid Engineering at UT, focusing on designing of functional materials. Internationally, I collaborate with Technische Universität Dresden (Germany) on advanced ceramics and Karlsruhe Institute of Technology (Germany) on Ni-based superalloys. Beyond Europe, I work with researchers from King’s College, Imperial College London (UK), alongside industrial partners like Rolls-Royce and UKAEA, focusing on thermomechanical fatigue of superalloys. Additionally, I've been a visiting researcher at the University of Oxford (UK). Furthermore, I've co-supervised MSc students with the company Reden.