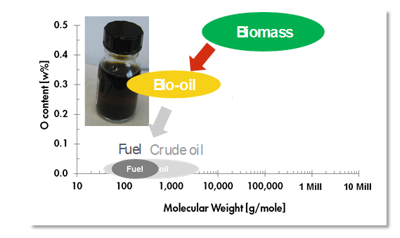

Process concepts are being explored to convert lignocellulosic biomass to bio-oil, which can subsequently be upgrade to liquid transportation fuels, e.g. by co-processing in a conventional oil refinery or, most recently, produce novel composite and coating materials. The field has been reviewed in depth (Lignocellulose Liquefaction to Biocrude, 2018). The studies carried out the university of Twente focused on the conversion processes that exploit high-boiling solvents and operate at moderate temperatures (300-320°C) and moderate pressures (40-60 bars).

One process concept explored by Maria Castellvi and Sushil Kumar uses the recycled bio-oil product as a liquefaction medium (Thesis_M_Castellvi Barnes and Thesis_S_Kumar). Recycled bio-oil appeared indeed to be very effective in liquefying the biomass to high degree. However, it becomes increasingly heavy and viscous upon recycling. Hence, a line of investigation is focusing on reducing or mitigating the formation of heavy product. This was attempted either by avoiding their formation e.g. through optimization of process parameters or the use of acid-base additives or by removing the heavy ends prior to recycle e.g. using a novel L/L extraction with T-swing.

Alternatively, Shushil Kumar also explored the possibility to avoid recycling the bio-oil with its heavy ends. Here, we explored the use of cheap hydrocarbon solvents that are present in oil refineries. One approach proposes a once-through by liquefying the lignocellulose in a typical FCC feed and feeding the resulting blend directly to the FCC unit. Another approach exploits the natural L/L demixing of bio-oil and hydrocarbons a room temperature to recover and recycle the hydrocarbon solvent.

Beyond developing process concepts, Maria Castellvi also try to better understand the chemistry of lignocellulose liquefaction. To this end, we undertook a detailed analysis of the bio-oil and recognized that it’s largely composed of phenolic components, without the water and sugar-like species found in pyrolysis oil. We also studied the liquefaction of the various constituents of lignocellulose and found the carbohydrates to be responsible for the undesired formation of char. In contrast, the lignin was responsible for the formation of heavy liquid products. Finally, Maria Castellvi also investigated the role of the solvent in more depth and concluded that the effectiveness of the solvent is due to chemical affinity (or solvation) of sugar-type components, e.g., as expressed in the distance between cellulose and solvent in the Hansen parameter space.

We also explore alternative uses for the liquefaction oil, e.g. for thermoplastic composites or thermoset coatings. We indeed found that, once isolated, the heavy fraction of biocrude is solid at room temperature but soften at elevated temperature. This thermoplast can then be reinforced with natural fibers to deliver a composite that shows a mechanical strength like polystyrene. Unlike conventional composite, however, this one can be easily recycled by reprocessing it into biocrude and, subsequently, blending its heavy fraction with fresh natural fibers. Alternatively, Qi-Song is showing that the heavy fraction of biocrude can be mixed with di-epoxides and thermally cured to form strong and hydrophobic coatings e.g. for woody materials. After use, the spend coated material can be turned to new biocrude feedstock for coating by reprocessing in liquefaction.