Introduction

ECN has developed an ammonia sensing device for measuring very low frequencies of ammonia in the atmosphere (down to 6 ng/m3). A hydrophobic membrane is used as liquid-gas interface. The sampled gas is examined using conductivity measurement. This apparatus is currently used as a reference monitoring instrument in the Dutch National Monitoring Network (of RIVM) and for field campaign ammonia measurements at several European sites. The overall dimensions of this existing system are that of a suitcase. The system is in production at R&R Mechatronics.

Figure 1. R&R ammonia detection system

Miniaturization of this device and integration of its key components on a chip may lead to several advantages, such as enhanced stand-alone measuring capability, reduced energy consumption and considerable decrease in reagent and waste volumes. The reduced reagent consumption will make it suitable medical applications where there is a demand for breath analysis systems. Ammonia breath analyzers can be applied for easy and convenient detection of H. Pylori infection that causes peptic ulcers.

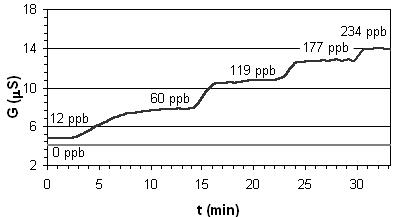

A miniaturized device can be realised using micro-system-technology in silicon and glass substrates: photolithography, etching, deposition of thin films and wafer bonding. These materials have the advantage that they do not absorb ammonia. Channels with a depth as low as 15 micrometer are etched in glass and are covered with a polypropylene, gas permeable and water repellent, membrane. The glass cover comprises a 100 micron deep gas channel that is powder-blasted into the glass substrate and conductivity sensors for detecting changes in the ion concentration. An impression of such a system is given in figure 2. Figure 3 shows a photo of a realized device. Figure 4 shows a preliminary ammonia detection result.

Figure 2. Impression of a micro fluidics ammonia detection system

Figure 3. Silicon part

Figure 4. Result

Interested?

If you are interested and for instance would like to do your graduation work or practical term, please contact via the email address below.