Biomass could provide the chemical industry with sustainable routes to the materials that are necessary to a modern and comfortable life. This promise requires the development of new conversion and separation technologies to be applied in future biorefineries.

In one workstream devoted to the production of cellulosic ethylene glycol, we are investigating pre-treatment technologies to extract carbohydrates from lignocellulosic biomass in a way that makes them suitable for subsequent upgrading by means of hydrogenation or hydrogenolysis. (Thesis Thimo Te Molder). To this end, We unraveled the critical role of biomass contaminant to be removed, namely alkali earth metal such as Ca2+ that precipitate the homogeneous W-based catalysts, the N- and S-containing extractives that poison the Ni-based hydrogenation catalyst and, to a lesser extent, the lignin that foul the Ni-based hydrogenation catalyst. We proposed a organosolv-type pretreatment to remove these contaminants.

Building on these learnings, Romolo Di Sabatino is exploring the possibility to apply a much simpler pre-treatment, namely a simple acid-wash, and modify the hydrogenolysis step to accommodate the lignin. To this end, we run the hydrogenolysis with organic co-solvent to solubilize the lignin and explored the impact of the co-solvent on the overall yield and the deactivation and recovery of the catalyst system.

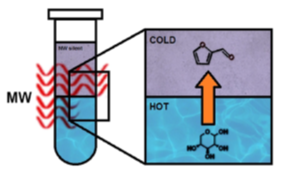

We are exploring novel chemistries to convert sugars to furanic intermediates that can subsequently be upgraded to chemical building blocks (Furfural, 2012 and Furfural manufacture and valorization, 2024). For instance, with Luca Ricciardi and Molecular nanoFabrication (MnF), we confirmed a pronounced acceleration in furfural production from  xylose under microwave heating and could assigned it to local overheating of the medium that result from inhomogeneous microwave irradiation. We then applied the learning to enhance reactive extraction in biphasic media: we applied microwave to selectively heat the aqueous reaction phase while keeping the organic extraction phase relatively cool and reached, thereby, very high furfural yields (Thesis_Luca_Ricciardi_2021).

xylose under microwave heating and could assigned it to local overheating of the medium that result from inhomogeneous microwave irradiation. We then applied the learning to enhance reactive extraction in biphasic media: we applied microwave to selectively heat the aqueous reaction phase while keeping the organic extraction phase relatively cool and reached, thereby, very high furfural yields (Thesis_Luca_Ricciardi_2021).

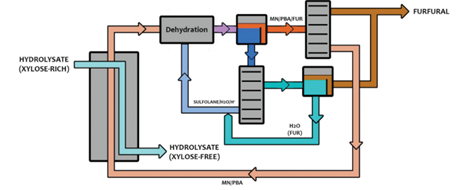

Luca Ricciardi also explored the potential of extracting sugars into organic media using boronate esters and, subsequently, convert the xylose boronate ester to furfural with ~90% selectivity. The latter step was successfully achieved by contacting the extracted phase with water-organic phase that forms a single phase with the extractant at reaction temperature (for facile conversion) but separate into a polar and apolar phase upon cooling (for facile furfural recovery). Another approach consisted in reacting the xylose ester in a biphasic system, in the presence of saline water. Integrated process concepts have been proposed to exploit these findings. (Thesis_Luca_Ricciardi_2021). Peter van der Wal is presently derisking the new approach to furfural manufacture by revisiting the choice of solvent and boronate extractant, by determining the kinetics and thermodynamics of the extraction and dehydration steps and determining the key parameter for designing the extraction reactors.

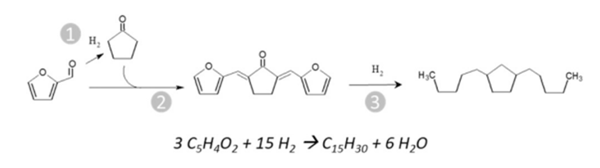

Beyond making furfural, Rick Baldenhofer is exploring the chemistry of converting furfural to sustainable aviation fuels and developing integrated process concepts for it. He showed the co-production of undesired oligomeric material during the rearrangement of furfural to cyclopentanone and developed various approaches to couple furfural and cyclopentanone to the desired trimer.

With Production Technologies (PT), we explore the possibility of developing thermoplastic bio-materials from the heavy and tarry product of lignocellulose liquefaction. We indeed found that, once isolated, the heavy fraction of biocrude is solid at room temperature but soften at elevated temperature. This thermoplast can then be reinforced with natural fibers to deliver a composite that shows a mechanical strength like polystyrene. Unlike conventional composite, however, this one can be easily recycled by reprocessing it into biocrude and, subsequently, blending its heavy fraction with fresh natural fibers.

In collaboration with Catalytic Processes and Materials (CPM), we are exploring the opportunity to upgrade bio-intermediates to chemical building blocks.

For instance, we have explored the possibility to use acetic acid, a natural fermentation product of sugars, as acylation agent to convert benzene to phenyl-ethanol, which can then be dehydrated to styrene. We also explored the possibility to upgrade propylene glycol, a major co-product of sugar hydrogenolysis, to acrylic acid. The route proceeds via dehydration to allyl alcohol followed by oxidation to acrylic acid. We also confirmed the possibility to convert furfural to furandicarboxylic acid (FDCA) by base-catalysed addition of CO2.

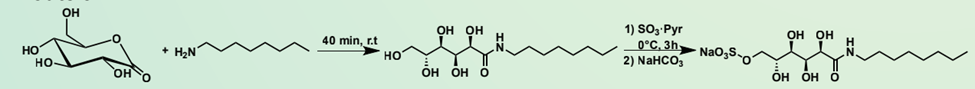

Philipp Effnert, from Molecular nanoFabrication (MnF), is developing sugar-based surfactants that comprise a polar head that is derived from glucose that is optionally sulphonated and an apolar tail derived from lipids or conventional oligomer of (bio)ethylene. He is exploring various form of sugar derivatives, e.g. with open and closed sugar structure, and various link between the polar and apolar segments.

However, a catalysis transformation does not suffice to provide a promising biorefinery concept;  separation technologies and conceptual process is also necessary. To this end, we are subjecting various projects to a conceptual process design and economic assessment. We are also developing concepts and guidelines to help the researchers identifying critical issues in the early stage of development (catalysis for biorefineries, 2016).

separation technologies and conceptual process is also necessary. To this end, we are subjecting various projects to a conceptual process design and economic assessment. We are also developing concepts and guidelines to help the researchers identifying critical issues in the early stage of development (catalysis for biorefineries, 2016).