Linear Polyamines for polyelectrolyte multilayer coated membranes

SPC (synthesis) and MST (membrane assembly)

Contact: Daniel Hagedoorn (d.hagedoorn-1@utwente.nl)

Background:

Polyelectrolyte multilayers (PEMs) are promising materials as selective separation layers.[1] They can be coated on membranes to further enhance the membrane capabilities. These PEM-coated membranes have a wide variety of applications, such as the treatment of challenging waste streams to remove organic contaminants or pharmaceuticals. The PEM membranes are an ideal setup, because, the charge and density of the PEMs can be tuned for the specific needs of the waste streams. To further improve these tuneable properties using well-defined polymers is key. For that poly(alkylene imine)s will be used, these polymers can be synthesized from activated aziridines using the so-called “living anionic polymerization” (LAP). LAP is a well-controlled polymerization technique, which leads to polymers with a low polydispersity and will allow us to prepare totally new polyelectrolytes, which were not accessible before. The LAP of activated aziridines has been developed in the SPC group, and the master project brings you to the state-of-the-art of this type of polymerization.

Chemistry and polymerization:

The student will start with synthesizing the building blocks, i.e. the aziridine monomers by Organic Chemistry. The monomers are bio-based or petroleum-based and will be prepared from amino alcohols or amino acids with a methyl, ethyl, propyl, or butyl side chain. This will give us access to a systematic library of new monomers, which then need to be polymerized using living anionic polymerization and finally, they need to be “deprotected” to release the free amines in the backbone (Scheme 1). For more background information on aziridines and their polymerization read the review from Wurm et. al.[2] or contact us directly. This master project is focussed on polymer synthesis and some experience in the field of synthetic chemistry is essential.

Membrane coating and analysis:

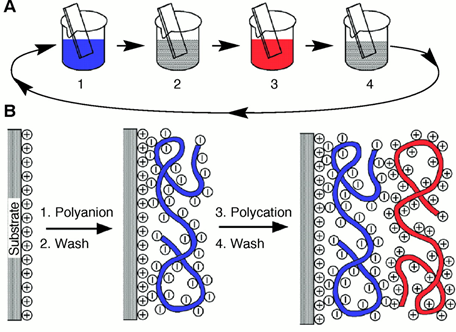

With the polymers in hand, the next step of the project can start, the membrane functionalization. The membranes will be coated with an anionic layer and a cationic layer to get a polyelectrolyte multilayer membrane (Scheme 2). After coating the membranes will be tested using forward osmosis to see how well the salt retention is with different salt solutions compared to the different side-chain length polymers.

Scheme 2. PEM formation[3]

References:

[1] D. M. Reurink, W. M. de Vos, H. D. W. Roesink, J. de Grooth, Ind. Eng. Chem. Res. 2021, 60, 7331–7341.

[2] T. Gleede, L. Reisman, E. Rieger, P. C. Mbarushimana, P. A. Rupar, F. R. Wurm, Polym. Chem. 2019, 10, 3257–3283.

[3] G. Decher, Science. 1997, 277, 1232–1237.