Polymer brushes in advanced grease lubrication

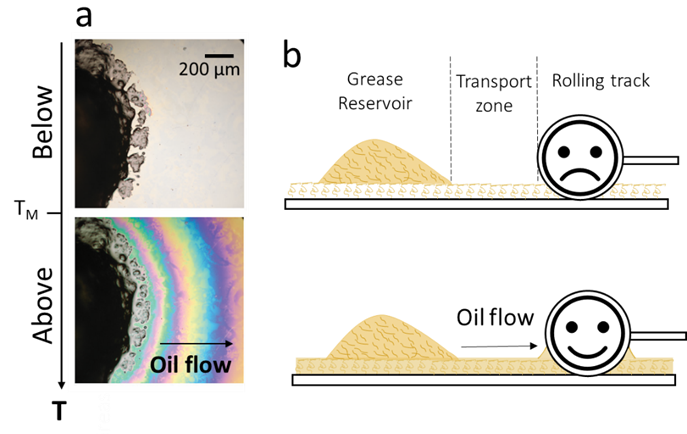

Lubrication greases are soft materials consisting of a self-assembled fibrous matrix filled with oil, which is gradually released during the operation of rolling bearings. The performance of these greases is crucial for the reliability and durability of bearings in applications like wind turbines and electric vehicles. To enhance lubrication systems, materials that can adapt to environmental changes are essential. In this project, you will explore the use of polymer brushes to simulate a bearing-like environment and investigate how oil migrates as the polymer brush layer swells. Polymer brush coatings are effective in modifying the properties of solid surfaces, such as reducing friction and adhesion, thanks to their responsiveness to external stimuli, like temperature. Specifically, surface-grafted P18MA polymer brush layers are in a solidified, semi-crystalline state at room temperature, preventing them from interacting with ambient fluids. However, when heated above their melting temperature (TM), these brushes swell and activate their ability to absorb and transport fluids. Figure 1a illustrates the melting-controlled ability to sorb and transport a solvent over macroscopic distances of hundreds of micrometres for a commercial lubrication Li/M grease. In this project, you will investigate the temperature-dependent oil transport capabilities of polymer brushes, using commercial Li/M grease as the oil source and observe the behaviour on a P18MA polymer brush layer in comparison to a flat surface. This study will offer valuable insights into how polymer brush-based coatings can enhance lubrication efficiency in real-world applications.

Fig. 1 a Optical top-view images of P18MA brushes below (top) and above (below) the melting transition in the presence of Li/M grease reservoir. b Schematic of a generic grease-lubricated contact as experimentally realized in a ball-on-disc tribometer with illustrations of three conceptual regions: grease reservoir, transport zone (stabilized by a surface-grafted polymer brush layer; below the melting transition (top), above the melting transition (bottom)) and rolling track with the contact area.

Research objective

The study will utilize commercial Li/M grease as the oil source, applied to a flat surface or treated with P18MA brush coatings. To simulate a bearing-like environment, a glass bead will be positioned at a fixed distance from the grease reservoir. The primary goal is to explore the improvement in oil transport from the grease reservoir to the rolling contact facilitated by these coatings.

Learning objectives

- Learn about thin polymer film, focusing on semicrystalline polymer brushes

- Learn about capillary and wetting phenomena

- Perform optical measurements (video microscopy) to monitor the oil transport

- Learn about optical image processing and interference-based thickness measurements

Daily Supervision: Luciana Buonaiuto; Vincent Siekmann.