New chemistry in a spinneret

- Persons involved: Keerthana K. Menon (PhD Candidate), Nieck Benes (promotor), Hannah Roth (co-promotor/supervisor)

- Duration: 2023-2027

- Funding: TNW FiF Sectorplan

Introduction

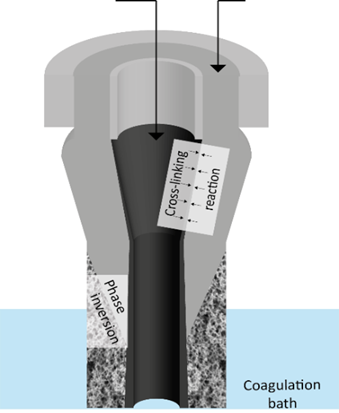

Membrane processes such as nanofiltration, gas separation and reverse osmosis mainly use thin film composite (TFC) membranes. A majority of the available TFC membranes are produced using interfacial polymerization (IP) on flat sheets. Hollow fiber membranes have several advantages over flat sheet membranes including a high packing density, a high surface area to volume ratio and self-supporting structure. Fabrication of hollow fiber membranes is done via dry-wet spinning of a polymer solution. Subsequently turning the fibers into TFC membranes with IP is time consuming and has a low success rate in hollow fiber geometry. In “Chemistry in a spinneret” method the polymerization reaction is conducted concurrently with dry-wet spinning, i.e., as a single step process. This work explores new chemistries that can be used for the polymerization reaction.

Key words

chemistry in a spinneret, interfacial polymerization, TFC membranes, hollow fiber membranes

Technological challenges

The main challenge in this project is finding a suitable polymerization reaction that can be combined with phase inversion to form high performance composite membranes.

Research questions

This project aims at combining the principles of chemistry in a spinneret and non-conventional interfacial polymerizations to develop thin film composite hollow fiber membranes in a single step for gas separation applications. The crosslinking of different monomer pairs will be explored for the development of the selective layer.

Principle of chemistry in a spinneret