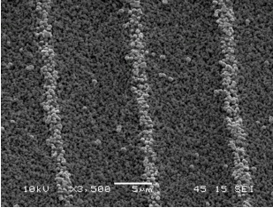

Barium titanate (BTO) is used as high-k dielectric phase in multi-layer ceramic capacitors (MLCC). The capacity of these devices is proportional to the dielectric constant of the BTO phase, and inversely proportional to the layer thickness. The minimum BTO layer thickness that can be achieved commercially with state of the art tape casting methods is about 0.5 - 1 µm, which implies the use of starting powders with a particle size of ca. 100 nm. Further miniaturization requires finer powders and new deposition techniques.

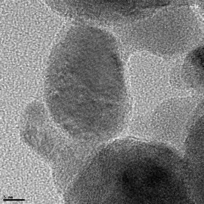

Figure left: Transmission Electron Microscopy picture of BTO nanoparticles; Figure right: Cross-section of MLCC, showing BTO phase (light grey) and Ni electrodes (dark grey).

Wet-chemical routes to synthesize BTO nanopowders and dispersions with suitable properties for ultra-thin film deposition are targeted in this project. Introduction of foreign elements into such dispersions is relatively simple and inexpensive, but too laborious to optimize. Therefore Pulsed Laser Deposition (PLD) is used to quickly screen doped systems. This technique enables fast deposition of thin films of extremely high quality with any given doping system, thus identifying suitable compositions for up-scalable wet-chemical syntheses.

Goals:

•Development of new synthesis routes enabling production of nano-sized BTO and versatile doping with foreign elements;

•Development of ultrathin films with a high dielectric constant from BTO nano-particles;

•Studies into doped systems and doping strategies in which foreign metals are incorporated to (1) inhibit grain growth, and (2) stabilize the tetragonal phase of BTO particles below a size of 50 nm.

This project is rendered by Tomasz Stawski, Sjoerd Veldhuis, and Ole Göbel.

Daily supervisor: André ten Elshof