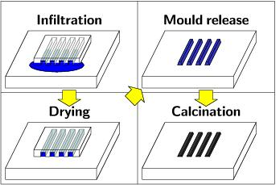

The application of some soft-lithographic techniques, e.g. microtransfer molding (µTM), Conventional Micromolding (µM) and specifically micromolding in capillaries (MIMIC) has proven to be a suitable, technically simple and low-cost route to obtain inorganic (mainly oxide) thin films with high fidelity. We make use of MIMIC to pattern ceramic suspensions and sol-gel precursors, where the patterns have periodicities typically between 1 and 5 µm. The MIMIC process is schematically depicted below.

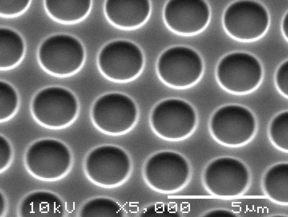

Elastomeric (PDMS) molds are typically obtained from relief patterned Si or photoresist masters. Subsequently, after the patterning step the precursor is subjected to a heat treatment in order to transform sol-gels into the oxide material or sinter suspensions to higher densities. An example is shown below.

These kinds of micropatterns are very generic structures and could therefore be applied in a wide range of applications, such as miniaturized electronic components, optical waveguides, luminescent pixel displays, scaffolds for biological tissue growth, etc. We are currently developing several kinds of oxide-based line and dot patterns. In order to understand the filling behavior/process of the capillaries better, we are also studying the wetting behavior of water on a number of potential materials for the elastomeric molds.

This project is carried out by Sajid Khan and Ole Göbel.

Daily supervisor: André ten Elshof