“I started studying Mechanical Engineering at a university of applied sciences but realised it wasn’t for me. I got frustrated with the focus on cost-cutting and simplicity in order to sell something to a company; this also took away all the creativity in the process. I missed the aspect of designing something that directly improves people’s lives.

That’s why I decided to continue with the Bachelor’s in Biomedical Technology at the University of Twente, where the focus was on contributing to medical care. Choosing the Master’s in Biomedical Engineering was the most logical next step for me as I wanted to gain more knowledge and skills in designing prostheses.

There are five specialisations, and I chose the specialisation in Medical Device Design because I wanted to focus on the design process. The other specialisations also involve elements of robotics and electrical engineering, but design has always been the part that interests me the most.

Solving real problems in healthcare

What I like about this Master's is that you can see the impact of your work: we’re tackling real-world problems in the healthcare sector. It feels so rewarding when you come up with something that could actually help people. I also like how theory comes to life. Back in high school, I thought, “When am I ever going to use maths?” Even in my Bachelor’s, I assumed I would only use a small part of what I learned. But in this programme, we apply all the theories we're learning.

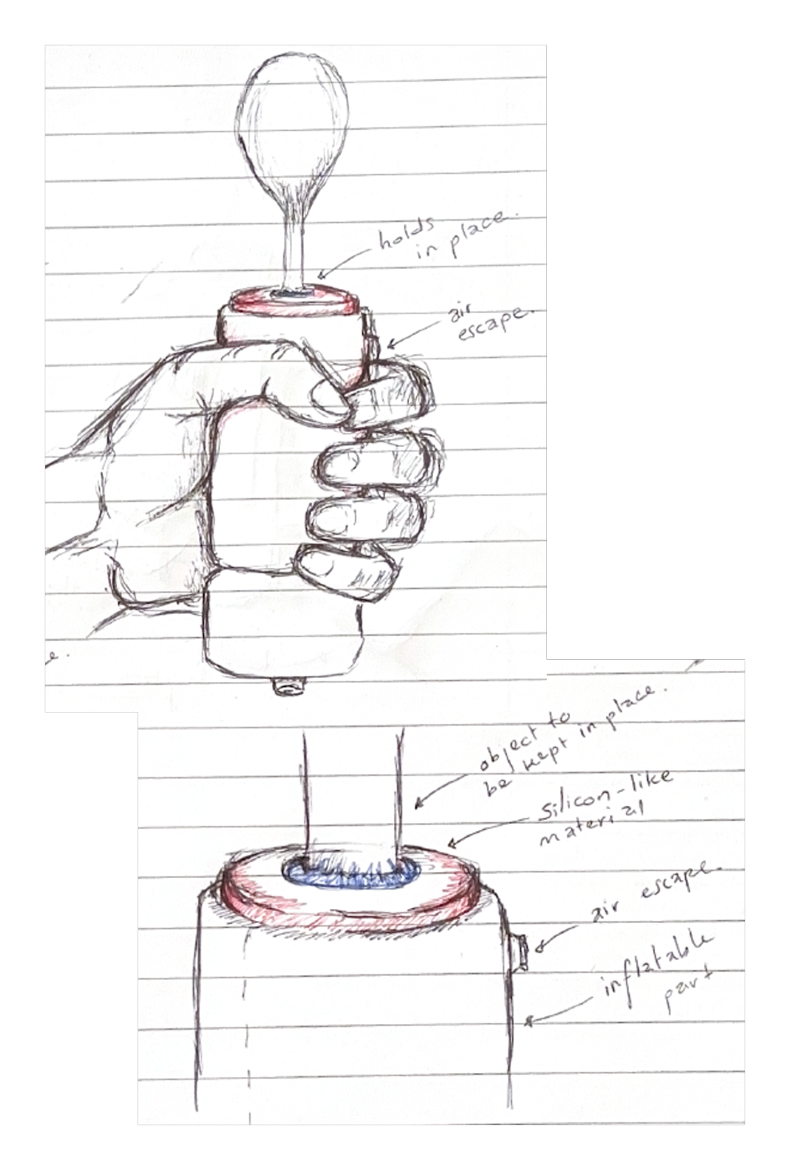

One of my favourite projects was designing an invention to help stroke patients train their hands as they lose muscle power. We designed a sort of squeezable hand trainer that allowed people to practice grip strength.

My team started by researching existing solutions and exploring ideas. Then, we had to think about how to get a medical device like this on the market, including meeting all the strict medical certification rules. That was something I hadn’t really thought about before and was interesting to learn. We even built a prototype to show how the device would work!

3D-printed casts

Another project that stood out to me was redesigning a 3D-printed cast meant to replace traditional plaster casts used in cases of injuries, such as fractures. Instead of getting a bulky cast when you break your arm, your arm would be scanned, and a custom 3D-printed cast would be made for you.

The original design wasn’t very practical, so we had to completely redesign it and make it better. Our new version is made from lightweight material and even has hinges to allow certain types of movement, which can help the healing of some fractures. It was a super exciting project because it combined medical innovation, design, and even thinking about medical certification and how to bring something like this to market.

My future

I’m still deciding whether I want to work in a hospital or for a company, but I know I want to design prostheses. Helping patients test and fit those to regain mobility or improve their quality of life would be amazing.

Everything I’ve learned in the Master’s is so practical, and it’s exciting to see how it all connects to the medical field. It’s given me confidence that I’m ready for the biomedical world, and that’s something I’m looking forward to.”