De Beer operates at the intersection of physics and chemistry and specialises in polymer coatings. She researches how these coatings can be used in scent sensors. As part of a large consortium with other educational institutions, companies, vets, and farmers, she’s developing an electronic nose that helps farmers quickly detect illnesses in their animals.

Sensor replaces the vet

Animal diseases are a major challenge for farmers. “When vets walks into a barn, they often immediately smell that something’s wrong,” says De Beer. “But farmers, who spend all day among the animals, don’t notice the change in scent. And of course, you can’t send vets everywhere, all the time.” De Beer and her consortium members began looking for a solution to this problem and came up with a portable sensor that measures changes in smell. Unlike most previous versions of the electronic nose, this sensor works in a way that’s more similar to the human sense of smell. De Beer notes another difference: “Existing sensors are large devices that consume a lot of power. You can’t just carry those into a barn. The sensor we’re developing will be much smaller, making it far more practical to use.”

From recognising whiskies to detecting drugs

The electronic nose has a wide range of potential applications — one of which was discovered by chance. De Beer explains: “We had created a setup that mimicked the human nose on a small scale. After testing a few typical scents, such as lavender, we spontaneously decided to see whether the setup could distinguish between different whiskies. Andriy Kuzmyn, the postdoc I’m working with, cycled to the shop and came back with miniature bottles of whisky. These different whiskies were clearly recognised by our setup.” More serious applications are also being explored, such as drug screening at customs, spoilage detection in the food industry, and maintenance of wind turbines.

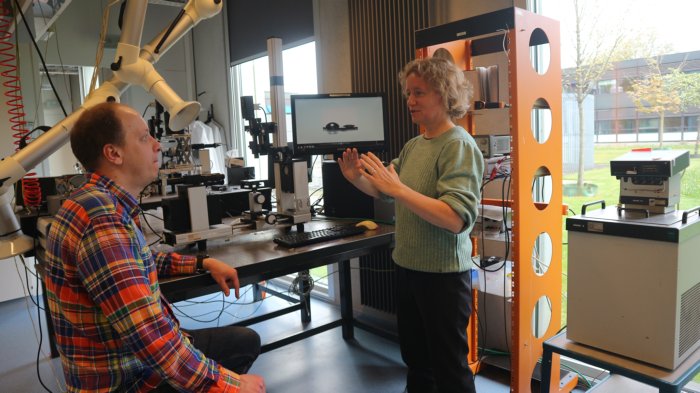

Andriy Kuzmyn and Sissi de Beer

A multidisciplinary project

Developing the sensor for use in livestock barns involves a range of disciplines. De Beer and her colleagues at the University of Twente and Saxion University of Applied Sciences are key to designing sensitive coatings that allow for reliable measurements. She explains how these polymer coatings work: “The coatings are made up of tiny hairs. Molecules settle in those hairs, causing the coating to swell. The swelling of different brushes on a sensor array varies depending on the scent, which allows us to distinguish between different scents.” The knowledge and experience of other researchers and companies that produce sensors is also vital in making the technology accurate and functional. Finally, the sensor needs to be built into a practical device suitable for use on farms. Input from both farmers and vets is essential to ensure the device fits into daily practice and is user-friendly. De Beer on this unique collaboration: “If you want to achieve something, you need to bring all those different disciplines together. In our lab, physics and chemistry meet — but in the wider project, technical expertise is combined with the expertise of farmers and vets. That sense of collaboration, working as a team towards a shared goal, is what I see as a key factor in the success of such projects.”

The challenge of variable environments

Alongside its successes, the development of the electronic nose also faces challenges. The new sensor is highly sensitive to changes in background conditions. De Beer explains: “Humidity levels in barns can vary a lot. The coatings we’ve developed react strongly to that. We want to prevent moisture from reaching the coatings — for example, by using a filter that blocks moisture but lets scent molecules through. Another option is to correct for humidity. That should be possible in theory, because the human nose can still recognise a scent whether it’s raining or dry. That’s because our brains are highly trained. We want to train the sensor in a similar way using machine learning, exposing it to a wide range of backgrounds so that it continues to recognise smells even in changing conditions.”

Smelling beyond human limits

The big question is whether this technology can outperform the human sense of smell. De Beer: “That is indeed our plan. The major advantage of polymer coatings is that they can absorb a lot of molecules. In the human nose, each receptor can only hold one molecule at a time. With the electronic nose, we can therefore theoretically detect lower concentrations than with the human nose. That means we should be able to detect things that humans aren’t even capable of smelling yet.”