Inorganic hollow fibers from facile and environmentally benign methods

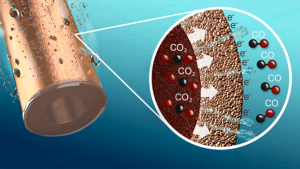

The university of Twente holds the world record for the thinnest inorganic hollow fibers, and has developed methods to produce thin inorganic hollow fibers without the use of organic solvents. The small diameters of the fibers can be achieved by the dry-wet spinning method followed by thermal treatment. A liquid mixture of a polymer, solvent, and inorganic particles is spun into a coagulation bath. In the coagulation bath the polymer is generally solidified by phase separation induced by a non-solvent. A subsequent thermal treatment allows for further viscous shrinkage of the fibers, the removal of the polymer, and the sintering of the organic particles. Within our group we have developed dry-wet spinning processes based on bio-ionic gelation instead of phase separation.

The thin inorganic porous hollow fibers provide large surface-area-to- volume ratios, and find for instance application as membrane (support) or as electrode.

For example see: doi:10.1038/ncomms10748