IMPACT OF MAGNET FIELD, TEMPERATURE, AXIAL AND TRANSVERSE CYCLIC LOAD ON THE SUPERCONDUCTING WIRE TRANSPORT PROPERTIES

Research financially supported by the ITER Organisation and F4E. ![]()

The great challenge of creating an optimal superconductor starts from basic materials science and requires an interdisciplinary approach combing fundamental and applied physics. Understanding the interesting and complex interaction of all individual aspects, e.g., lattice strain, material diffusion processes, magnet field, current and potential distribution and thermal instability, requires dedicated scientific research and modeling. One of the most crucial aspects for eventual application of superconducting composites (wire or cable) in magnets is the strong dependency between lattice strain state and transport properties. The fascinating scientific results of this work are used for comprehending the relations between material science, fundamental physics and applied superconductivity. The appealing benefit and aim of this work is superconductor development for energy- applications, - transport and magnets ranging from small scale systems like MRI, NMR to prestigious international projects like ITER and CERN. To this aim, dedicated and unique experimental facilities have been developed, which led among others to milestones like the famous ITER Ic(B,T,ε) scaling relation and the innovative ITER TF conductor improvement.

Some of the research methods developed within EMS also serve for (ITER) wire qualification tests. (The University of Twente is a qualified ITER Reference Laboratory).

ITER conductors and performance

The spectacular transport properties of most superconductors depend on strain and in particular large and complex composite conductors, like the ITER Nb3Sn Cable In Conduit Conductors (CICC), suffer from this feature. The performance depends largely on the thermal and electromagnetic (EM) load because of the open nature of the ITER cable pattern with periodic strand to strand support and accumulation of the forces through the layers of the cable. Liquid He provides cooling to almost 4 K by using the open spaces in the cable. On top of that the different wire processing methods (Internal Tin, Bronze, Powder In Tube, (Ti, Ta additions, variation Sn %) result in diverse critical current-strain sensitivity and mechanical stiffness, so research on the basic material properties, electromagnetic – mechanical mechanisms and processing methods is inevitable.

Critical surface Jc(B,T,ε)

The maximum values of temperature, electrical current and magnetic field are interdependent and the pictures below show the critical surface for a superconductor, which is the boundary between superconductivity and normal resistivity in 3 dimensional space (see plots below) for the most widely used technical superconductors, NbTi and Nb3Sn. In addition we have the strain as a 4th parameter.

Critical surface of Nb3Sn (red), Nb-Ti (green) and MgB2 (blue) versus temperature T and magnetic field B.

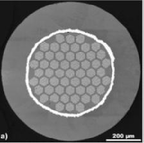

Superconductors must be formed into composite wires and then cabled to be used in high current applications. Superconducting wire is almost always of a multifilamentary design in which individual continuous filaments (< 5 μm in diameter for ITER) are embedded in a high conductivity matrix (see below). When conditions in a localized region of a superconductor exceed the critical surface, that area will start to conduct resistively producing local heating. The resulting heat and current transfer will start a cascade effect and result in a rapid transition of the whole superconductor to the normal state (quenching).

An example of a multifilamentary superconducting strand with sub-element assembly (shown is a bronze processed wire). Micrographs from P.J. Lee, FSU, FL, USA.

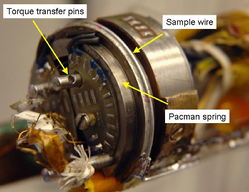

Strain affects the transport properties of most superconducting materials. We developed devices with various probes to characterise experimentally the impact of different types of loading on the transport properties of strands. A unique and versatile facility is TARSIS (Test ARrangement for Strain Influence on Strands) and also the first of its kind, the Pacman. With the results of these investigations we can quantify the influence of strand material, processing and design properties on the transport performance. In combination with dedicated cable models we are able to predict design changes aiming for meaningful performance improvement.

An example of a multifilamentary superconducting strand with sub-element assembly (shown is an internal tin processed wire). Micrographs from P.J. Lee, FSU, FL, USA.

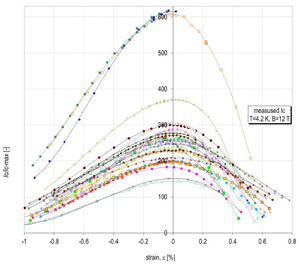

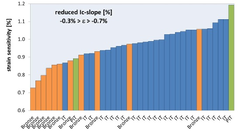

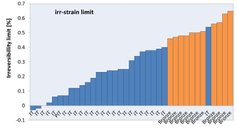

Axial strain variation and critical current

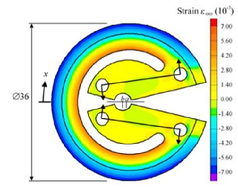

The Pacman is a spring (see pictures below) for application of controlled axial compressive or tensile strain. The wire is soldered around a circular spring which can be deformed in giving controlled axial compressive or tensile strain at varying temperature (T=2 to 77 K).and magnet field (B=0 to 15 T). The current can be controlled between zero and 2000 A (see below). A selction of typical critical current versus axial strain curves for different types of strands is shown in the plots below, together with irreversibility limits and strain sensitivity. The device is used to develop the Ic(B,T,ε) scaling relation for Nb3Sn material, which is adopted by ITER for scaling of the wire transport properties.

![]()

The Pacman is a spring for application of controlled axial compressive or tensile strain.

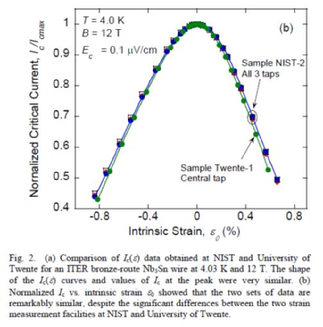

A selection of typical critical current versus axial strain curves for different types of conductors (left) and the strain sensitivity and irreversibility limit of mostly internal tin and bronze wires (right).

Benchmarking result from 2011, comparing the normalised Ic data obtained at NIST on a Walter Spring with those measured on the Pacman at the University of Twente.

Precision Vertical Linear Stage

The Precision Vertical Linear Stage is the warm part of the set-up, on top of the cryostat to exert the load for all TARSIS probes. It is configured for automatic cycling, the minimum displacement is 40 nm and the maximum load amounts to 20 kN (load cell), (see photo below). The full bending probe with instrumentation and wiring, and some of the details of the cap with bulges and extensometers are shown as well. The voltage current transition of the wire is measured in applied magnet field at 4.2 K under controlled variable load or displacement.

The Precision Vertical Linear Stage

Mounted bending probe

Details of the bending probe showing the cap with bulges and one of the extensometers

Periodic bending of superconductors

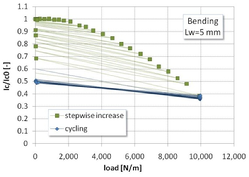

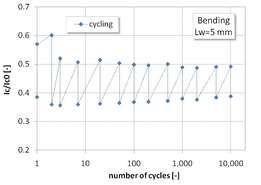

The wires in a multi-stage cabled CICC are periodically supported and clamped by surrounding wires in the cable bundle. When subjected to a transverse electromagnetic force, this results into periodic bending and pinching of the wires. The effect of a spatial periodic bending pattern on the transport properties is tested along 150 mm strand length in a TARSIS bending probe. We have developed probes for wavelengths from 3 to 10 mm (distance between bulges). A typical result is shown below, representing the reduction in transport properties (critical current) depending on the applied load and the number of load cycles.

Reduction of critical current depending on the applied load (left) and the number of load cycles (right).

Periodic and homogeneous contact stress on superconductors

The effect of a spatial periodic contact stress pattern (pinching) on the transport properties is investigated along 150 mm strand length in the TARSIS crossing strands probe. Below (left) a photo of a crossing (X)-strands probe is shown with the wire sample mounted, heat treated and tested on the same (TiAlV) holder to avoid handling. Straight X-strands, also reacted, are pressed by the top plate (see right).The same probe can be used for homogeneous applied load by replacing the crossing wires by a flat ring, shown in the middle and with the load cap at right. The strand deformation (compression) is measured with the extensometers used for the bending probes.

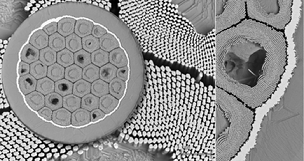

TARSIS probes for periodic contact (left) and homogeneous applied load (2nd & 3rd). At right a section from a wire after testing with periodic contact stress.

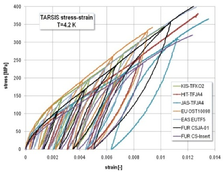

Axial tensile stress-strain characterisation

The axial stiffness of strands is important to withstand the load and resulting deflection during bending and magnet hoop stress. A TARSIS probe has been developed and is shown below with a few results on ITER type of Nb3Sn wires.

Axial tensile stress-strain probe with sample and extensometer.

Results of stress strain curves obtained on several ITER Nb3Sn wires.

Utilization of the results

This unique set of wire tests are crucial for the understanding of the basic phenomena related to strain. Moreover, the results were the fundamental basis and input for the TEMLOP model (see elsewhere this site), predicting the improvement of the Nb3Sn ITER conductors by changing the twist pitch sequence and lengths.

Both devices, TARSIS and Pacman, are also used as a qualification test for all ITER strands to be applied in the ITER magnet system.

Not only Nb3Sn wires are tested in this facility but also other strain sensitive wires like MgB2 types are investigated and further developed in collaboration with wire manufacturers.

For more information, please contact Arend Nijhuis: ![]()

![]()

Links: ITER, F4E

Papers on this subject

- S. Wessel, A. Nijhuis, Y. Ilyin, W. Abbas, B. ten Haken and H.H.J. ten Kate, ‘A Novel “Test ARangement for Strain Influence on Strands” (TARSIS): Mechanical and Electrical Testing of ITER Nb3Sn Strands’ Advances in Cryogenic Engineering, Materials, Vol. 50, pp.466-473, 2004

- A. Nijhuis, Y. Ilyin and W. Abbas, B. ten Haken, and H.H.J. ten Kate, ‘Effect of Periodic Cyclic Deformation on the Voltage Current Transition of Nb3Sn Strands Tested in the Novel ‘TARSIS’ Setup’, IEEE Trans. Appl. Supercond., Vol. 14, No. 2, (2004), pp. 1464-1467

- N. van den Eijnden, A. Nijhuis, Y. Ilyin and W.A.J. Wessel, H.H.J. ten Kate ‘Axial tensile stress strain characterisation of ITER Model Coil type Nb3Sn strands in TARSIS’, Supercond. Sci. Technol. 18 (2005) 1523–1532

- A. Nijhuis, N. van den Eijnden, Y. Ilyin, E.G. van Putten, G.J.T. Veening, W.A.J. Wessel, A. den Ouden, and H.H.J. ten Kate, ‘Impact of Spatial Periodic Bending and Load Cycling on the Critical Current of a Nb3Sn Strand’, Supercond. Sci. Technol. 18 (2005) S273–S283

- A. Nijhuis, W.A.J. Wessel, Y. Ilyin, A. den Ouden, and H.H,J. ten Kate, ‘Critical current measurement with spatial periodic bending imposed by electromagnetic force on a standard test barrel with slots’ Rev. Sci. Instrum. 77 (2006) 054701

- A. Nijhuis and Y. Ilyin, ‘Transverse Load Optimisation in Nb3Sn CICC Design; Influence of Cabling, Void Fraction and Strand Stiffness’, Supercond. Sci. Technol. 19 (2006) 945-962. IOP Select: articles chosen by our Editors for their novelty, significance and potential impact on future research. IOP Select reflects both the breadth and international significance of papers published in our prestigious peer reviewed journals

- A. Nijhuis, Y. Ilyin, W.A.J. Wessel, ‘Spatial periodic contact stress and critical current of a Nb3Sn strand measured in TARSIS’, 2006 Supercond. Sci. Technol. 19 1089-1096. SUST 2006 Highlights, selected by the editorial board to highlight the quality of research published in Superconductor Science and Technology in 2006, Thomas Miller, Publisher

- A. Nijhuis, Y. Ilyin, W.A.J. Wessel, W. Abbas, ‘Critical current and strand stiffness of three types Nb3Sn strand subjected to spatial periodic bending’, 2006 Supercond. Sci. Technol. 19 1136-1145

- A. Nijhuis, Y. Ilyin, W.A.J. Wessel, W Abbas, ‘Spatial periodic bending and critical current of bronze and PIT Nb 3Sn strands in a steel tube’ 2007 IEEE Trans Appl Supercond 17, pp. 2680-2683

- A. Nijhuis, Y. Ilyin, W. Abbas, 2008 ‘Axial and transverse stress-strain characterization of the EU dipole high current density Nb3Sn strand’, Supercond. Sci. Technol. 21, 065001 (10 pp)

- A. Nijhuis, ‘A solution for transverse load degradation in ITER Nb3Sn CICCs: verification of cabling effect on Lorentz force response’ Supercond. Sci. Technol. 21, (2008) 054011 (15pp)

- A. Nijhuis, W.M. de Rapper, Y. Ilyin, W.Abbas, W.A.J. Wessel, H.J.G. Krooshoop, ‘Solution for Lorentz forces response and degradation in Nb3Sn cable in conduit conductors; verification of cabling effect’, IEEE Trans Appl Supercond 18 2008, p1491-5

- A. Nijhuis, Y. Ilyin, W. Abbas, WAJ Wessel, HJG Krooshoop ‘Performance of ITER (EU-TFPRO-2) Nb3Sn strands under spatial periodic bending, axial strain and contact stress’, IEEE Trans Appl Supercond 18, 2008, p 1059-62

- A. Nijhuis, Y. Ilyin, W. Abbas, W.A.J. Wessel, H.J.G. Krooshoop, L. Feng, Y. Miyoshi, ‘Summary of ITER TF Nb3Sn strand testing under axial strain, spatial periodic bending and contact stress’, IEEE Trans Appl Supercond 19 (2009) p 1516-20

- A. Nijhuis, R.P. Pompe van Meerdervoort, W.A.J. Wessel, ‘Spatial periodic and homogeneous transverse stress loading on ITER TF Nb3Sn bronze and internal tin strand’ IEEE Trans Appl Supercond 22, 2012

- N. Cheggour, A. Nijhuis, H. J. G. Krooshoop, X. F. Lu, J. Splett, T. C. Stauffer, L. F. Goodrich, M. C. Jewell, A. Devred, and Y. Nabara, ‘Strain and Magnetic-Field Characterization of a Bronze-Route Nb3Sn ITER Wire: Benchmarking of Strain Measurement Facilities at NIST and University of Twente’ IEEE Trans Appl Supercond 22, 2012

- R. Vasilyev, N. Kozlenkova, A. Vorobyeva, V. Pantsyrny, A. Nijhuis, ”Performance characterization of Russian ITER Nb3Sn Strands”. IEEE Trans Applied Supercond 21, art. no. 5699955, pp. 2505-2508

- Y. Miyoshi, E.P.A. van Lanen, M.M.J. Dhallé, A. Nijhuis ‘Microscopic Fractures and Transport Degradation in ITER Type Nb3Sn Strands’, IEEE Trans App Supercond 20 (2010) 1404-7

- Y. Miyoshi, W.A.J. Wessel, E.P.A. van Lanen, Y. Ilyin, M.C. Jewell, M. Dhallé, H.H.J. ten Kate and A. Nijhuis ‘Filament fracture distribution in a bronze and internal tin ITER type Nb3Sn strand’, Proceedings of ICEC 22 – ICMC 2008, edited by Ho-Myong CHANG et al. (2009) The Korea Institute of Applied Superconductivity and Cryogenics 978-89-957138-2-2, p. 951

- Y. Miyoshi, E.P.A. van Lanen, M.M.J. Dhallé, and A. Nijhuis ‘Distinct voltage-current characteristics of Nb3Sn strands with dispersed and collective crack distributions’, Supercond. Sci. Technol. 22 (2009) (7 pp.) p 085009

- A. Nijhuis, Y. Miyoshi, M.C. Jewell, W. Abbas, W.A.J. Wessel, ‘Systematic study on filament fracture distribution in ITER Nb3Sn strands’, IEEE Trans Appl Supercond 19 (2009) p 2628-32

- K Osamura, A Nyilas, M Thoener, B Seeber, R Fluekiger, Y Ilyin, A Njihuis, J Ekin, C Clickner, RP Walsh, V Toplosky, H Shin, K Katagiri, S Ochiai, MHojo, Y Kubo and K Miyashita, (2008) International round robin test for mechanical properties of Nb3Sn superconductive wires at room temperature’, Supercond. Sci. Technol. 21 045006 (10pp)

- Y. Ilyin, A. Nijhuis, W.A.J. Wessel, W. Abbas, ‘Scaling law for the strain dependence of the critical current in an advanced ITER Nb3Sn strand’, Supercond Sci Technol 20 (2007) 186–191

- A. Godeke, M. Dhalle, A. Morelli, L. Stobbelaar, H. van Weeren, H.J.N. van Eck, W. Abbas, A. Nijhuis, A. den Ouden and B. ten Haken, ‘A Device to Investigate the Axial Strain Dependence of the Critical Current Density in Superconductors’, Review of Scientific Instr. 75,5112-5118 (2004)

- L. Bottura, B. Bordini, Jc(B,T,ε) Parameterization for the ITER Nb3Sn Production, IEEE Trans App Supercond, 19 2009, p 1521