High-speed liquid microjets generated by cavitation bubbles have gained significant attention due to their applications in fluid dynamics, material processing, ink-jet printing and biomedical engineering.

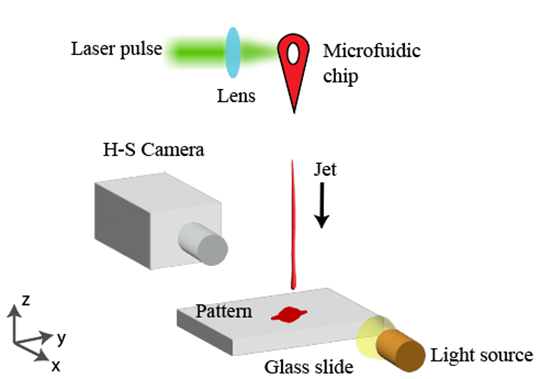

These microjets are transient, non-continuous flows with unique instability modes. When such jets impact substrates, their oscillatory nature (e.g., axis switching) and energy dissipation mechanisms create complex linear patterns, which depend on parameters like nozzle geometry, jet velocity, and the distance between the nozzle and the substrate. Our system uses a pulsed laser focused on a microchamber filled with liquid to produce the cavitation bubble, while a high-speed camera records the jetting and impact process. This study aims to explore the linear patterns formed by high-speed liquid microjets impacting a glass substrate and how these patterns change when jet speed varies for different nozzle-substrate distances.

Assignment

1. Learn to effectively and safely operate a pulsed laser system

2. Produce and control high-speed liquid microjets generated by cavitation bubbles.

3. Measure and characterize key liquid properties, including surface tension, density, and viscosity.

4. Analyse the dependence of jet impact patterns on jet speed and nozzle-substrate positioning.

Contact information

Claudia Muñoz Villaescusa (c.munozvillaescusa@utwente.nl)