The research group Inorganic Membranes (IM) of the Faculty of Science and Technology of the University of Twente is involved in different aspects of the science and technology of dense and porous inorganic membranes. The scientific staff consists of two external professors (Arian Nijmeijer and Wilhelm Meulenberg) and three staff members (Marie-Alix Pizzoccaro-Zilamy, Mieke Luiten-Olieman, Aayan Banerjee), who are responsible for the three following themes, around which our research is structured.

NANOSTRUCTURED POROUS MEMBRANES

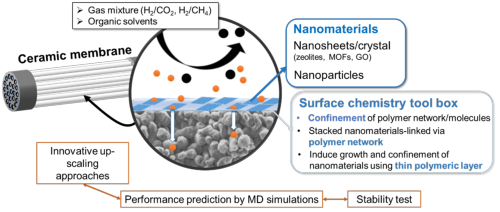

The nanomaterial chemistry toolbox offers an infinite perspective to engineer porous membranes with nanoscale features for separations under challenging and demanding conditions, such as the separation of H2 from CO2 or the recovery of organic solvents. Nanochannels can now be prepared via sol-gel chemistry or by using two-dimensional nanomaterials (e.g. graphene oxides, zeolites, metal-organic frameworks). Further, textured surfaces can be engineered via the nanoconfinement of smart polymer brushes/molecules or surface polymerization of organic networks in/on porous ceramic supports.

The goal of the Nanostructured Porous Membranes theme is to develop the next generation of hybrid porous membranes which will push further the combination of nanomaterials and surface-modification science. We develop new synthesis approaches and study the influence of the preparation conditions on membrane performance and properties. To achieve a complete control of the behaviour and properties of the resulting hybrid/inorganic porous membranes, it is essential to understand their microstructure. To meet this goal, in-depth characteristics of the membrane and inter/intraparticle interactions are required. Molecular dynamic simulations accelerates this process by providing insights into the nature of these interactions and their influence on the separation behaviour of gases or solvents.

To take a concrete step, we will have to identify not only innovative material combinations but also innovative synthesis approaches with promising scale-up routes. In the end, new, robust, highly reproducible, and easy-to-scale-up methods will become available for the production of defect-free hybrid nanostructured-based membranes.

The Nanostructured Porous Membranes theme is also hosted within the Membrane Division of Materials Synthesis and Processing (IEK-1), at the Forschungszentrum Jülich where a part of the activities are carried out. For details about these activities, see: FZ-Jülich webpage.

For more information please contact: m.d.pizzoccaro@utwente.nl

DESIGN OF MEMBRANES BY LAYER DEPOSITION TECHNIQUES

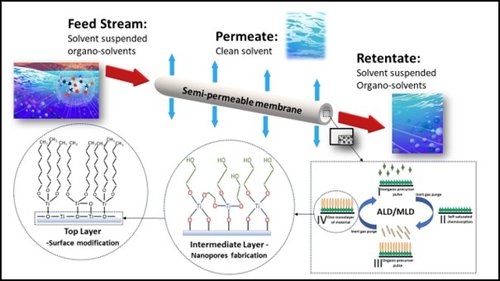

Many large (10 – 100 m³/h) industrial process streams contain solvents or water-with-solvents mixtures with organic components or particles. Recycling solvents can be extremely worthwhile in terms of carbon footprint and environmental impact. Organo-solvent nanofiltration ceramic membranes can be made with Atomic Layer Deposition (ALD), known for its unparalleled control over layer thickness and 3D conformality. However, large ceramic membranes do not fit in state-of-the-art ALD systems.

We have designed a novel atmospheric ALD reactor for tuning the pores on the nanoscale of the semi-permeable ceramic membrane. Additionally, organic molecules can be incorporated into the membrane layers with Molecular Layer Deposition to functionalize the surface in the pores of the membranes.

For more information please contact: m.w.j.luiten@utwente.nl

DENSE CERAMIC FUEL CELLS, ELECTROLYSERS, AND MEMBRANE REACTORS

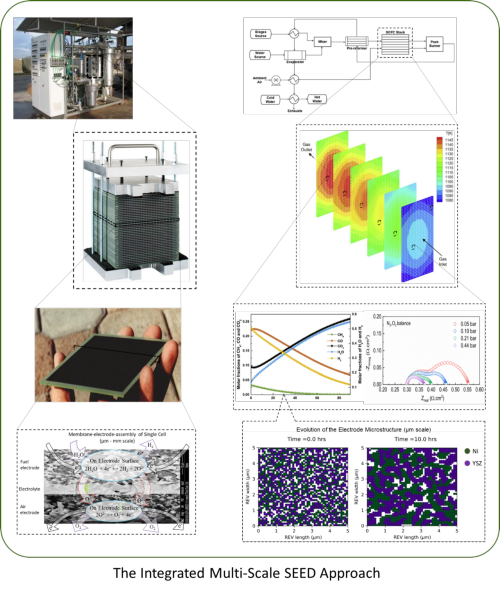

Research within this theme is done in the Sustainable Electrochemical Engineering and Digitalisation (SEED) lab, under the guidance of Dr. Aayan Banerjee. SEED works on the design, control and scale up of next-generation chemical and electrochemical technologies from innovative lab-scale devices to novel industrial processes by combining local operando characterization and performance testing with integrated multi-scale multi-physics digital twins (from catalyst/electrode surfaces to industrial unit systems). SEED closely collaborates with the IM research group on the theme of intermediate to high temperature dense ceramic membrane-based reactors and electrochemical devices. These include solid oxide and protonic ceramic fuel cells and electrolysers.

You can find more information about this theme on the SEED website or contact Dr. Aayan Banerjee