Within the NWO-TTW Perspectief Program “Innovative Magnetic Density Separation for the optimal use of resources and energy” (2016-2021, link), EMS is designing and assembling several superconducting magnet systems for use in Magnetic Density Separation (MDS).

MDS is a new recycling technology that combines a ferro-fluid with a high-gradient magnetic field to separate non-magnetic materials, such as shredded plastics or electronic waste, based on their mass density. In the NWO Program, a consortium of Dutch universities (Delft, Eindhoven, Enschede, Nijmegen and Utrecht) and companies is generating the knowledge and technology to develop MDS further into a widely-applicable recycling process on an industrial scale. MDS will thus contribute important savings of energy and material resources, by recycling high-value materials instead of producing them from ore or oil.

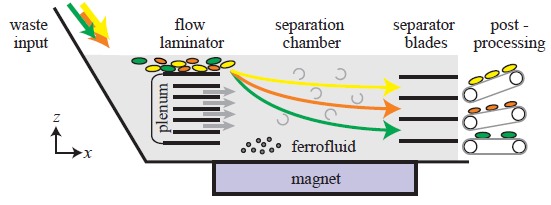

The MDS principle is illustrated in the figure. At the left, the materials to be separated are mixed into the ferro-fluid which carries them through a magnetic field with a strong vertical gradient. Competition between gravity acting on the materials and the magnetic force on the fluid causes the particles to seek an equilibrium height that is determined by their mass density. Physically separating the thus stratified stream on the right of the system, various density fractions are straightforwardly sieved out for further processing.

Schematic representation of an MDS system.

The task of EMS concerns the development of superconducting magnets that enable considerably higher field gradients and deeper fluid beds than those achievable with permanent magnets or copper-iron electromagnets. These conventional techniques are now used to realize field gradients of the order of 5 T/m and fluid beds of 10 cm height, whereas the NWO Program aims to achieve at least 16 T/m and 30 cm. This will directly benefit separation resolution as well as throughput. The major challenge in the design of the superconducting magnet systems lies in minimizing the distance between their conduction-cooled racetrack coils and the ambient-temperature ferrofluid whilst reconciling the conflicting requirements of a robust mechanical structure and an adequate thermal insulation.

Contact:

- Dr. M.M.J. Dhallé

- Prof.dr.ir. H.J.M. ter Brake